AUTO DUCT LINE Ⅱ

首页 » HVAC AUTO DUCT LINE II

Auto Duct Production Line

- Contact Us

Brand: DURMAPRESS

Function

- Electric decoilers (2 sets of rollers) driven by independent frequency controlled motors.

- Multi-functional main body with capability of leveling,beading, notching(capable of sharp notching, TDF notching) and plate shearing.

- Mitsubishi computer controlling system and software.

- Mitsubishi and Siemens electric box and electrics.

HVAC Rectangular Duct line Square duct Auto Prodution Line II for Square Duct Forming Making.

Function Overview:

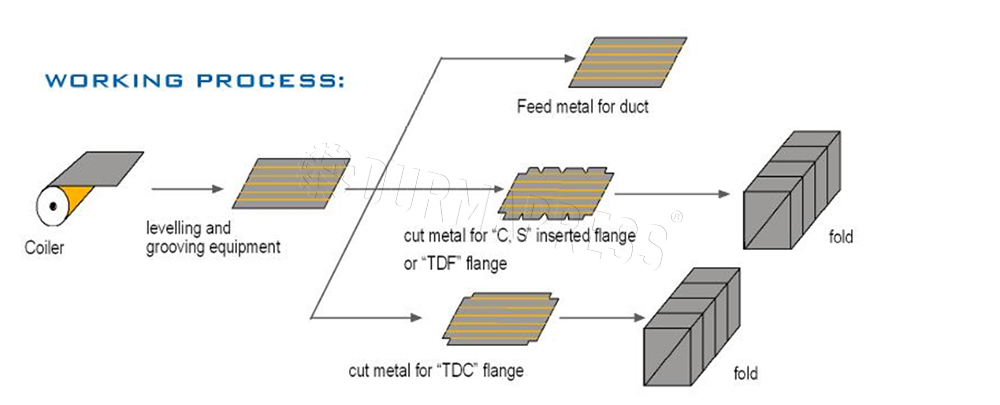

Auto Duct Line 2 feeds material for HVAC duct and TDF flange production, performing leveling, grooving, notching, and cutting.

Compatibility & Design:

It works with TDF flange, Pittsburgh lock, folding, and corner machines. The aluminum alloy suspension arm ensures easier operation.

Structure & Components:

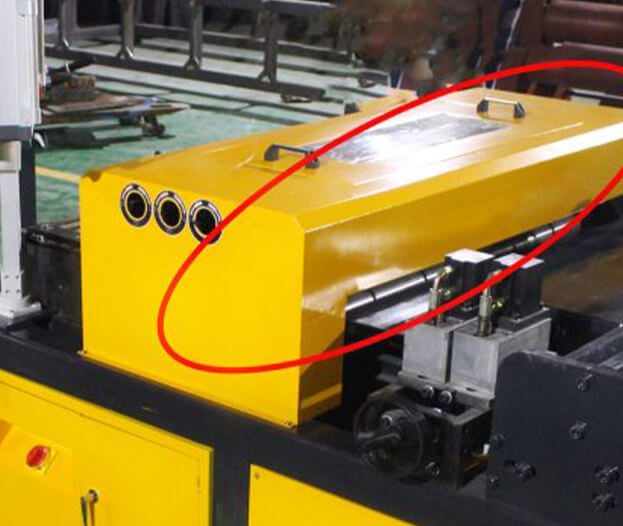

Built-in control cabinet simplifies wiring and improves mobility. Equipped with reliable imported systems like Mitsubishi CNC, Schneider electrics, Huade/Taiwan hydraulics, and Omron encoder.

Standard & Optional Configurations:

Includes 1 electric coil rack (2 trays), leveling/beading unit, hydraulic notching with 4 molds, shearing machine, and CNC system. Optional upgrade to 2 racks (4 coils) available.

Flexibility & Usability:

Available as a full CNC line or separate mobile units. It’s user-friendly, handling four key processes: leveling, beading, notching, and shearing.

- Japan Mitsubishi CNC control system+Schneider electrical system

- Beijing Huade or hydraulic system from Taiwan

- Japan Omron encoder

- One electric coil cradle (two material trays)

- One set leveling and beading equipment

- Hydraulic angle-shearing machine with four sets of die

- Hydraulic sheet-shearing machine

- A set of CNC computer control system and production software

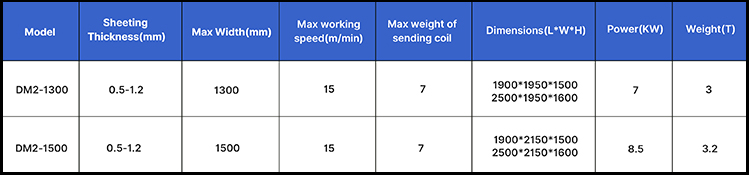

- Technical Data

- Production Details

Machine Frame

The machine frame adopts welding square steel,annealing treatment and overall processing to ensure the stability and flatness of the frame and processing accuracy.

PLC Control

Use Germany Siemens PLC controller which can accurately control the machining length,particularly suitable for production of ”L” and”口“-shaped pipe with different size.

Decoilers

Double coilers with adjustable coiling diameter of 500-600mm, loading capacity of each coiler reaches to 7T, driven by high-performance motor and reducer, which significantly improve

the practicability of coiler.

Loading Feeder

The upper loading feeder is supported with a rubber bearing to prevent the plate surface from cratching, and the ight and left sides are equipped with adjustable supporting arms.

Feeding Inlet

The feeding inlet is provided with a secondary feeding guiding rack to ensure feeding accuracy and improve its property against deviation.

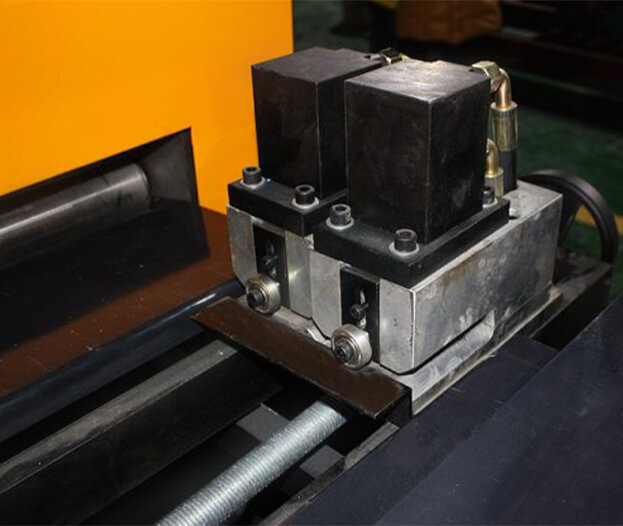

Angle notching

Notching”V””口”groove, the dies are made by Cr12Mov material with longer service life. Cutting angle and depth are adjustable, convenience for production.

Rollers

Use 2 feeding rollers, 4 leveling rollers, 2 beading rollers, all made by 45# quenched and tempered steel through fine grinding, chrome-coated treatment to ensure the roller strength and service life. beading slope distance is 210mm,driven by inverter motor, through Omron encoder transmitting signals to ensure the feeding stability.

Bevel gear and spur gears are made by SAE8620H material to reduce wear and improve the gear life span.

Sheet Cutting

Cutting method: holding-down on up side,hydraulic transmission, the blade is made by 6CrW2Si steel that can cutting stainless steel,cutting thickness within 0.5-1.2mm.

- Why Choose Us

Industry Experts

Professional HVAC Duct Machines Manufacturer

Perfect After-sales

24-hour after-sales response service

Engineer Overseas Service

Our engineers provide 24/7 on-site technical support

- Frequently Asked Questions

- You can choose the shipping company on your own. Or use our forwarder, we will quote you the CIF price.

- If less than one container,we will choose LCL (less container load), it will be cost-efficiency. If you purchase two and above, we will use 20″, 40″ or HQ container according to the machines size.

DURMAPRESS is a mature brand in China. We have CE, ISO and SGS certification to prove our quality. We welcome your visit, seeing is believing.

- T/T (30% advance payment, and 70% balance paid one week before shipment)

- L/C (100% L/C at sight), this should be negotiated first.

We always prepare stock for our clients. Contact us to learn more details.

Normally 15 days.

- Write Us