PNEUMATIC CORNER MOUNTING MACHINE

首页 » PNEUMATIC CORNER MOUNTING MACHINE

Rectangular Duct Making Machine

- Pneumatic Corner Mounting Machine

- Contact Us

Brand: DURMAPRESS

Function

- Automatic Corner Code Assembly:Accurately installs corner codes on workpieces like rectangular ducts. The Pneumatic corner mounting machine can finish one corner code assembly in about 6 seconds, fully replacing manual labor, boosting assembly efficiency and cutting labor costs.

- Improve Assembly Precision:Through precise mechanical control and positioning systems, it ensures accurate and firm installation of corner codes on workpieces. This guarantees the structural strength and stability of workpieces. For example, in the construction of doors, windows, and curtain walls, it can ensure the connection precision between corner codes and aluminum profiles, making installations more stable and sealing better.

- Enable Automated Production:Can cooperate with other production equipment (e.g., CNC feeding machines, punch presses) to form an automated production line. This achieves full-process automation from raw material processing to corner code assembly, enhancing production efficiency and product quality stability, while reducing manual intervention and production costs.

- Adapt to Various Workpieces and Corner Code Types:Some Pneumatic corner mounting machines can handle different specifications and shapes of workpieces and corner codes. By adjusting molds, clamps, or parameter settings, they meet the needs of different products, featuring strong versatility and flexibility for corner code assembly in multiple industries.

- Enhance Production Safety:Compared with manual assembly, the machine is simpler to operate, reducing the complexity and danger of manual operations and lowering the risk of worker injuries. Meanwhile, it usually has safety protection devices (e.g., emergency stop buttons, safety light curtains) to further ensure operator safety.

It’s used for installing rectangular duct corner code automatically to replace workers. This machine is easy to operate, it will take about 6 seconds to complete the installation for one corner and it replaces installing for the corner by hand completely, which is fast, time saving and effective, and this corner code assembly machine can make the rectangular duct connected better. Corner code assembly machine is the necessary equipment for rectangular duct production, this corner code assembly machine work with corner punching machine when the angle corner produced from corner punching machine, then the corner code assembly machine will automatically install the corner code onto the rectangular duct.

- Simple structure in linear type, easy in installation and maintenance.

- Adopting advanced world famous brand components in pneumatic parts, electric parts, and operation parts.

- High-pressure double crank to control the die opening and closing.

- Running in a high automatization and intellectualization, no pollution.

- Apply a linker to connect with the air conveyor , which can directly inline with filling machine.

- One motor

- One electronic box

- One control electric system

- One cylinder

- One foot switch

- Four pulley

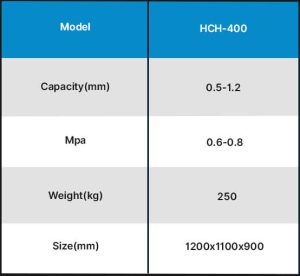

- Technical Data

- Final Producrs

Shipping & Packing

Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

- Why Choose Us

Industry Experts

Professional HVAC Duct Machines Manufacturer

Perfect After-sales

24-hour after-sales response service

Engineer Overseas Service

Our engineers provide 24/7 on-site technical support

- Frequently Asked Questions

- You can choose the shipping company on your own. Or use our forwarder, we will quote you the CIF price.

- If less than one container,we will choose LCL (less container load), it will be cost-efficiency. If you purchase two and above, we will use 20″, 40″ or HQ container according to the machines size.

DURMAPRESS is a mature brand in China. We have CE, ISO and SGS certification to prove our quality. We welcome your visit, seeing is believing.

- T/T (30% advance payment, and 70% balance paid one week before shipment)

- L/C (100% L/C at sight), this should be negotiated first.

We always prepare stock for our clients. Contact us to learn more details.

Normally 15 days.

- Write Us