PNEUMATIC FOLDING MACHINE

首页 » PNEUMATIC FOLDING MACHINE

Rectangular Duct Making Machine

- Contact Us

Brand: DURMAPRESS

Function

- Folding forming: Applies pressure to the edge of materials through mechanical devices to bend them into predetermined angles and shapes, forming neat folds, suitable for processing metal sheets, etc.

- Seaming connection: Can tightly connect the edges of multiple materials to form firm seams, often used in fields such as air duct production and metal structure assembly.

- Improving production efficiency: Features fast operation speed, capable of quickly completing folding work for a large number of materials, significantly shortening the production cycle.

- Ensuring processing precision: Can precisely control the angle, depth and position of folding, ensuring consistent product quality and meeting high-precision processing requirements.

- Adapting to various materials: Suitable for processing various materials such as metal sheets, plastic sheets and composite materials, with different models adjustable according to material characteristics.

- Easy operation: Has a simple and understandable operation interface, allowing operators to master it proficiently after short-term training; some are equipped with automatic counting, positioning and other functions.

- Reducing labor intensity: Reduces the workload of manual folding, especially advantageous when handling large or heavy materials, improving work comfort.

- Environmental protection and energy saving: Generates less pollutants such as dust and noise during operation, has little impact on the environment and operators' health, and has relatively low energy consumption.

Pneumatic folding machine is mechanical equipment driven by compressed air, used for bending material edges. It’s widely applied in metal processing, electronics, packaging, etc.

This machine adopts an all – steel welded structure and uses pneumatic power as the power source. According to the specifications, it is widely used for bending and processing steel plates with a length of less than 3 meters and a thickness of 0.3 – 2 millimeters to achieve the purpose of forming. This machine tool is easy and fast to operate, and is a forming and processing equipment for the cabinet and door manufacturing industry, stainless steel kitchenware, heating and ventilation, air – conditioning equipment and other box bodies, and air duct industries.

1.Working Principle

Compressed air enters the cylinder, making the piston rod extend to drive the folding die for bending. After bending, the rod retracts and the die resets, completing a cycle.

2.Structural Composition

Pneumatic system: Consists of air pump, cylinder, air pipe, valve, providing power.

Folding die: Designed into various shapes/sizes for different bending needs.

Workbench: Holds materials to be folded, with clamping devices to fix materials.

Control system: Controls the pneumatic system, realizing start/stop, angle/stroke adjustment.

3.Features

Efficient & energy – saving: Quick response, high production efficiency, low energy consumption.

Easy to operate: Simple button/handle operation, easy maintenance.

High precision: Accurately controls cylinder stroke/pressure, ensuring bending precision.

Safe: With overload protection and safety valve; the valve opens to release pressure when over – limit, protecting equipment and operators.

4.Application Fields

Metal processing: For bending metal plates, used in auto parts, home appliance shells, metal furniture production.

Electronics: Folds electronic product shells, circuit boards, enhancing appearance and protection.

Packaging: For folding packaging materials like cartons, 纸盒(paper boxes), plastic packages.

Construction: Processes building decoration materials, metal doors/windows, improving appearance and sealing.

- One foot switch

- One cylinder

- One electric control system

- One punch mold

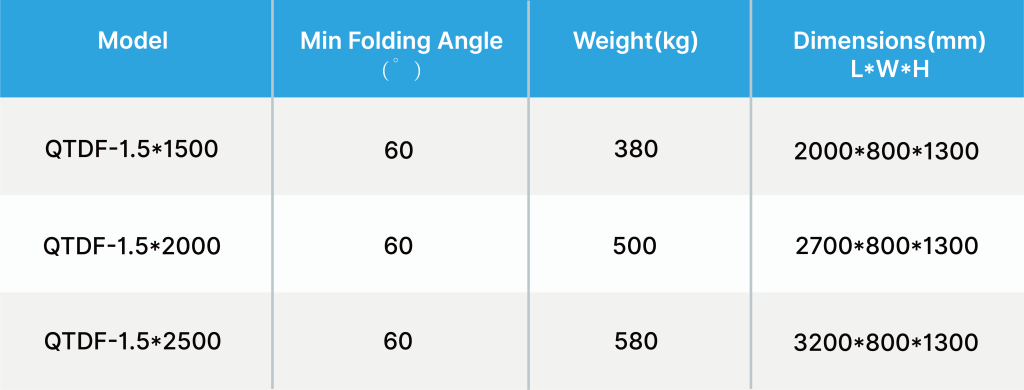

- Technical Data

- Shipping & Packing

Shipping & Packing

Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containersand ship them abroad.

- Why Choose Us

Industry Experts

Professional HVAC Duct Machines Manufacturer

Perfect After-sales

24-hour after-sales response service

Engineer Overseas Service

Our engineers provide 24/7 on-site technical support

- Frequently Asked Questions

- You can choose the shipping company on your own. Or use our forwarder, we will quote you the CIF price.

- If less than one container,we will choose LCL (less container load), it will be cost-efficiency. If you purchase two and above, we will use 20″, 40″ or HQ container according to the machines size.

DURMAPRESS is a mature brand in China. We have CE, ISO and SGS certification to prove our quality. We welcome your visit, seeing is believing.

- T/T (30% advance payment, and 70% balance paid one week before shipment)

- L/C (100% L/C at sight), this should be negotiated first.

We always prepare stock for our clients. Contact us to learn more details.

Normally 15 days.

- Write Us