In modern HVAC duct manufacturing, efficiency, consistency, and scalability are no longer optional—they are essential. As project sizes grow and delivery timelines shorten, traditional manual or semi-automatic duct fabrication methods struggle to keep up. This is where the auto duct line becomes a core production solution.

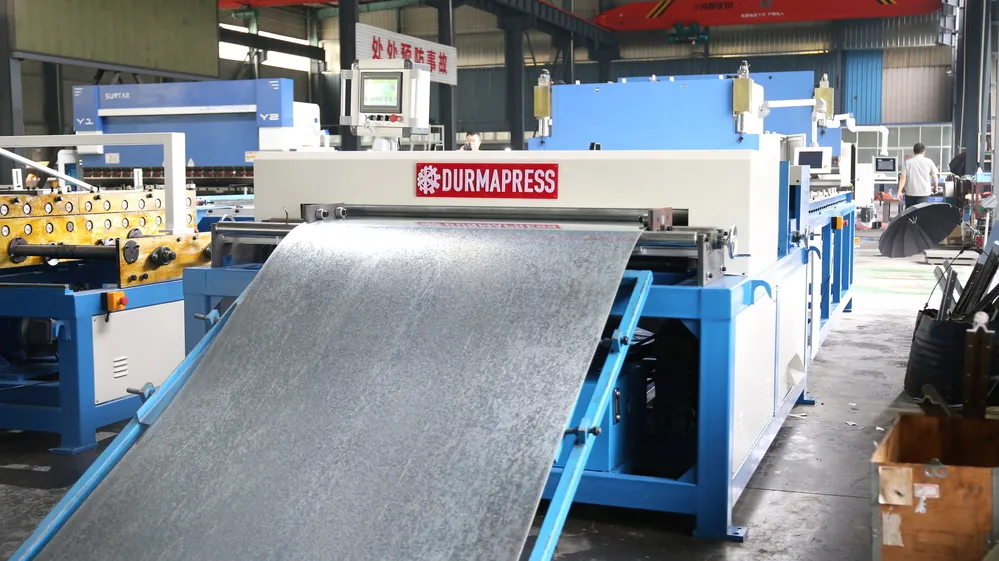

An auto duct line is a fully or semi-automated system designed to manufacture rectangular HVAC ducts through a continuous, integrated workflow. Instead of relying on separate standalone machines and manual handling, it combines feeding, cutting, forming, grooving, and locking processes into a single coordinated production line.

What Is an Auto Duct Line?

An auto duct line is an automatic duct production system used primarily for rectangular HVAC duct manufacturing. It processes sheet metal coils into finished duct sections through a sequence of synchronized operations, controlled by a centralized system.

Unlike individual duct machines that require repeated manual loading and repositioning, an auto duct line operates as a continuous manufacturing line. Once material parameters are set, the system feeds, processes, and outputs duct components with minimal operator intervention.

From a manufacturing perspective, it is not just a machine, but a production methodology designed for high-volume, standardized duct fabrication.

Why Auto Duct Lines Are Used in HVAC Manufacturing

The widespread adoption of auto duct lines in HVAC production is driven by clear manufacturing challenges.

Traditional duct fabrication methods often suffer from:

Inconsistent quality due to manual handling

High labor dependency

Limited production capacity

Bottlenecks between isolated processes

An auto duct line addresses these issues by introducing automation and process integration.

From an operational standpoint, manufacturers benefit from:

Higher production efficiency through continuous processing

Improved dimensional consistency across duct sections

Reduced labor requirements, especially for repetitive tasks

Predictable output, which simplifies project planning

As HVAC projects become larger and more standardized, automated duct production becomes a practical necessity rather than a luxury.

Main Components of an Auto Duct Line

While configurations vary, most auto duct lines are built around the same functional modules. Understanding these components helps clarify how the system operates as a whole.

Feeding and Cutting Section

Production begins with sheet metal coils being loaded onto the feeding unit. The material is automatically straightened and fed into the line, ensuring stable alignment before processing.

The cutting section then performs precise length cutting based on predefined duct dimensions. Accuracy at this stage is critical, as it directly affects downstream forming and assembly quality.

This section establishes the foundation for dimensional control throughout the entire duct manufacturing process.

Forming, Grooving, and Locking Units

After cutting, the sheet metal passes through a series of forming and edge-processing stations.

These units may include:

Roll forming for duct shaping

Grooving operations for edge preparation

Seam locking or folding mechanisms for structural integrity

During edge preparation, duct grooving is applied to ensure proper alignment and reliable connections in downstream forming operations. Rather than treating these as separate processes, the auto duct line integrates them into a continuous flow. This integration ensures consistent edge quality and reliable mechanical connections between duct sections.

The result is a duct component that is ready for assembly without additional manual correction.

Control System and Line Integration

At the core of the auto duct line is its control system. Typically PLC-based, it synchronizes each station to maintain stable production speed and accurate positioning.

Operators input duct dimensions, material thickness, and production parameters through a central interface. Once configured, the system coordinates feeding speed, cutting timing, and forming sequences automatically.

This level of integration allows the entire line to function as a single production unit rather than a collection of independent machines.

How an Auto Duct Line Works in Production

From a production workflow perspective, an auto duct line follows a logical and repeatable sequence:

Sheet metal coils are fed and aligned

Material is cut to programmed lengths

Edges are processed through forming and grooving

Seams or connections are mechanically locked

Finished duct sections exit the line

Because each step is synchronized, material moves smoothly from one process to the next without stopping. This continuous flow is what enables high output while maintaining consistent quality.

For manufacturers handling repetitive duct sizes, this workflow dramatically reduces setup time between production batches.

Common Types of Auto Duct Lines

Auto duct lines are often categorized based on configuration complexity and automation level. Rather than focusing on model numbers alone, it is more useful to understand their functional differences.

Entry-level configurations focus on basic feeding, cutting, and forming, suitable for smaller workshops with moderate output requirements.

Mid-level systems introduce additional forming and locking stations, allowing more complex duct profiles and higher throughput.

Advanced auto duct lines are designed for industrial-scale production. They feature higher automation, integrated quality control, and the ability to handle a wide range of duct sizes with minimal manual adjustment.

This range of configurations allows manufacturers to select a system aligned with their production volume and operational goals.

Auto Duct Line vs Standalone Duct Machines

A common question in HVAC manufacturing is whether an auto duct line should replace standalone duct machines entirely.Compared with a standalone duct forming machine, an auto duct line integrates multiple processes into a single coordinated workflow.

Standalone machines—such as individual forming, grooving, or bending units—offer flexibility and lower initial investment. They are suitable for customized production or low-volume environments.

However, compared to an integrated duct production line, standalone setups typically require:

More manual handling

Additional floor space

Higher labor input per duct

An auto duct line prioritizes throughput, consistency, and workflow efficiency, making it better suited for standardized, high-volume duct manufacturing.

In practice, many facilities combine both approaches, using auto duct lines for core production and standalone machines for special components.

Typical Applications in HVAC Duct Production

Auto duct lines are widely used across commercial and industrial HVAC projects.

Common applications include:

Commercial building ventilation systems

Industrial HVAC duct networks

Large-scale centralized air conditioning projects

They are particularly effective in environments where rectangular duct production is repetitive and volume-driven. In such cases, automation significantly improves delivery speed while maintaining uniform quality.

As energy efficiency standards tighten and HVAC systems grow more complex, consistent duct fabrication becomes increasingly important.

How to Choose the Right Auto Duct Line

Selecting the right auto duct line is not simply a matter of choosing the most advanced system available. The decision should be guided by production realities.

Key factors to consider include:

Expected production volume and peak demand

Range of duct sizes and material thickness

Available workshop space and layout

Level of automation desired versus operator involvement

A well-matched auto duct line should support current production needs while allowing room for future expansion.

Conclusion

An auto duct line represents a fundamental shift in how HVAC ducts are manufactured. By integrating multiple fabrication processes into a single, automated workflow, it enables higher efficiency, better consistency, and scalable production capacity.

For manufacturers facing increasing demand and tighter project schedules, an automatic duct production line is not just equipment—it is a strategic investment in long-term manufacturing capability.

FAQ

An auto duct line is used to manufacture rectangular HVAC ducts through a continuous, automated process. It combines feeding, cutting, forming, and locking operations to produce duct sections efficiently and consistently, especially for high-volume projects.

Most auto duct lines are designed for rectangular HVAC ducts. Depending on configuration, they can handle different duct sizes, material thicknesses, and connection styles used in commercial and industrial HVAC systems.

An auto duct line integrates multiple processes into a single production workflow, while standalone machines perform individual operations separately. Integrated lines reduce manual handling and increase output consistency, whereas standalone machines offer more flexibility for low-volume or custom work.