In modern HVAC manufacturing, an automatic duct line is the backbone of any efficient duct workshop. Instead of cutting, notching and forming each panel by hand, a well‑configured line takes coils of sheet metal in at one end and delivers ready‑to‑assemble ducts at the other, with consistent quality and much lower labor cost. This article breaks down every major component in a typical automatic duct line, so that workshop owners, HVAC contractors and project managers can read a configuration sheet with confidence and know exactly what they are paying for.

By the end, you will understand how each section—from coil handling and leveling to notching, cutting, lock forming and flanging—works together, and how to choose the right configuration for your HVAC projects and ducted AC systems.

What Is an Automatic Duct Line?

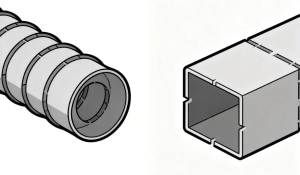

An automatic duct line (also called an auto duct line or HVAC duct production line) is a set of machines connected by conveyors, sensors and a central control system to fabricate rectangular or round air ducts from metal coils. It typically combines decoiling, leveling, notching, punching, cutting, folding, lock forming and flange forming into a continuous workflow, often operated by just a few people instead of a full manual team.

Coil Handling and Decoiler Section

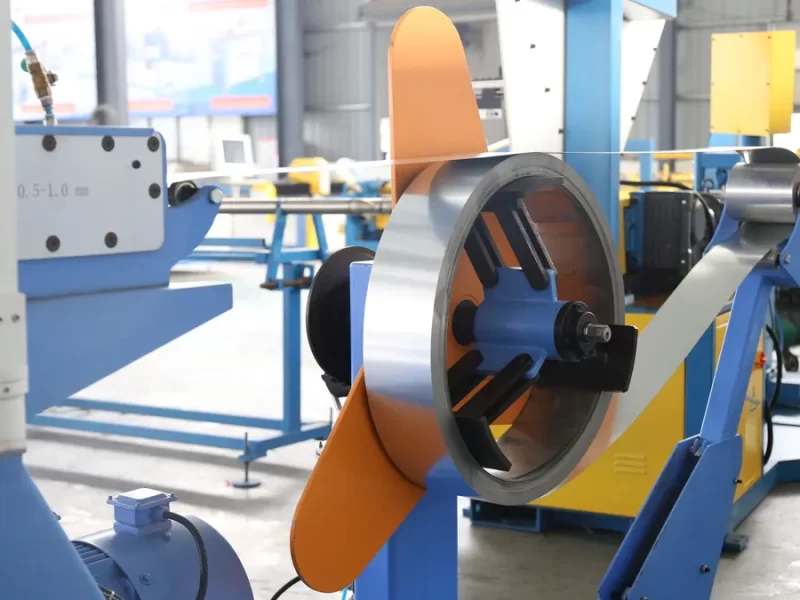

In any automatic duct line, the coil handling and decoiler section is where consistent quality and high throughput truly begin. This front‑end module takes raw galvanized steel, stainless steel or aluminium coils and feeds them into the line with stable tension and accurate alignment, setting the foundation for precise punching, cutting and forming downstream.

Decoiler / Uncoiler

A decoiler (or uncoiler) supports the coil, expands its mandrel to grip the inner diameter and smoothly releases sheet metal into the line at a controlled speed. Automatic duct lines typically use powered decoilers with adjustable expansion range to handle common HVAC duct materials from about 0.5–1.5 mm thickness and coil widths up to roughly 1,250–1,550 mm, depending on the line model.

For multi‑size production, a twin‑head or twin powered decoiler allows operators to load two coils at once and switch between materials with minimal downtime. This is especially useful when a workshop needs to alternate between different gauges or materials—for example, standard galvanized ducts and heavier gauge pieces for high‑pressure sections—within the same shift.

Feeding Rack and Leveler / Straightener

After decoiling, the sheet passes through a feeding rack and leveler (also called straightener) that removes coil set and waves from the strip. A set of upper and lower leveling rollers bends the material alternately up and down in small amounts, relieving internal stress and delivering a flat sheet to the notching and punching units.

High‑quality leveling is critical because any remaining curvature will directly affect length accuracy, diagonal tolerance and the leakage class of the finished rectangular duct. Many modern duct lines also integrate beading or ribbing rollers in this section to press stiffening ribs into large‑size panels, which increases rigidity without adding extra material or manual work.In durmahvac‑recommended duct lines, the leveling and beading section is tuned for stable production of large rectangular ducts used with our ducted indoor units.

Notching, Punching and Marking Units

Once the sheet is flat and straight, it enters the notching and punching area, where openings and cut‑outs are made for flanges, corners and connections. This section has a huge impact on how easy the duct will be to assemble and how clean the final joints are.

V‑Notching and Corner Notching Units

V‑notching units cut V‑shaped pieces out of the sheet corners so that, when the panel is folded, there is no extra metal overlapping in the corners. For TDC or TDF flange ducts, additional square or rectangular notches are made to create the space needed for forming the integral flange profile and fitting corner pieces.

When the notching station is configured with multiple tooling groups, the line can complete several types of notches in one pass—such as flange corners, access‑door cut‑outs and reinforcement holes—reducing manual layout and drilling later on. This not only saves labor but also ensures every duct corner is identical, which improves sealing and appearance on site.

Punching and Marking

Punching units create holes for bolts, hangers, access doors and other hardware according to the nesting program. In more advanced lines, inkjet or mechanical marking systems can print part numbers, folding marks or installation notes on each panel to guide assembly in the workshop or at the jobsite.

With a well‑designed punching and marking section, installers can quickly identify each duct piece and assemble it with fewer mistakes, which is especially valuable on large commercial projects with thousands of ducts and fittings.

Cutting and Folding / Forming Section

After notching and punching, the sheet is ready to be cut to final length and formed into duct shapes. This section determines much of the line’s output speed and dimensional accuracy.

Shearing / Cutting Unit

The cutting unit is usually a hydraulic guillotine shear or a flying shear integrated into the line. The control system measures the coil feed length via encoder and triggers the shear at the exact position, so each blank matches the programmed dimension within a tight tolerance (often around ±0.5 mm in typical configurations, depending on machine quality and maintenance).

Good cutting accuracy is essential for keeping rectangular duct diagonals within spec, reducing rework and ensuring that joints, flanges and seals fit properly. When combined with optimal nesting software, precise cutting also helps reduce scrap and lowers the cost per square meter of duct produced.

Bending, Folding and Panel Forming

Once cut, panels enter the folding or bending section, where edges are bent up to form the sides of the duct. In many rectangular duct lines, a folding unit can perform straight bends and complete “L”, “U” or even fully wrapped “口‑shaped” ducts in sequence. This reduces manual handling between machines and ensures that every fold angle is consistent across the batch.

Lock Forming, Flanging and Finishing Section

Towards the end of an automatic duct line, the focus shifts from flat blanks to forming strong, airtight connections that will hold up in real‑world HVAC systems. This is where lock forming, flange forming and optional sealing units turn cut panels into ducts that can be quickly assembled on site with minimal leakage.

Pittsburgh Lock Forming Machine

A Pittsburgh lock forming machine creates the characteristic female and male seams that allow two duct pieces to interlock without separate fasteners. By rolling specific profiles into the sheet edges, the machine forms a pocket (Pittsburgh seam) on one side and a complementary right‑angle flange on the mating piece, which are then hammered or “zipped” together to create a strong, airtight joint.

In an in‑line automatic duct line, the Pittsburgh lock profile can be formed automatically right after cutting and folding, so operators receive panels that are already prepared for quick assembly. This eliminates extra handling between stand‑alone machines, reduces labor intensity, and keeps seam quality consistent across an entire production batch.

TDF / TDC Flange Forming Machines

For many rectangular HVAC ducts, especially in commercial projects, integral flanges such as TDF (transverse duct flange) or TDC are widely used. A TDF/TDC flange forming machine roll‑forms the flange profile directly on the duct edge, creating a robust frame that can be joined with corners and bolts without separate angle iron welding.

Advanced automatic duct lines can complete notching, forming TDF or angle steel flanges, and folding into L, U or fully wrapped ducts in a continuous flow, greatly improving efficiency and material utilization. For large cross‑section ducts used with high‑capacity ducted HVAC systems, this integrated flanging and folding dramatically shortens fabrication time while keeping joints tight and reliable.

Optional Sealing and Finishing Units

Depending on the target leakage class and project requirements, the finishing section may also include automatic sealing, hemming or duct zipper units. These modules can apply sealant to critical seams, close hems on thin‑gauge metal and quickly close Pittsburgh locks, further reducing manual operations and improving consistency across the line.

Control System, Software and Automation Level

Behind all the mechanical modules is the control system, which synchronizes coil feeding, notching, punching, cutting and forming according to the production program. Most modern lines use PLC‑based control with servo drives for precise movement and repeatable positioning.

The operator inputs duct sizes or imports data from CAD/CAM or BIM software, and the nesting program automatically optimizes how parts are laid out on the coil to minimize waste. The control panel then coordinates each station, monitors encoders and sensors, and adjusts speed to keep the line running smoothly while protecting the machines from overload.

Higher‑end systems may also provide production reporting, remote diagnostics and integration with factory MES, making it easier for managers to monitor output, material consumption and machine status in real time.

How to Choose the Right Automatic Duct Line for Your HVAC Projects

Choosing the right automatic duct line is about balancing capacity, automation level and investment with the actual project mix your workshop handles.

Annual Volume and Duct Types

Start with your expected annual duct area and typical project size. High‑volume shops serving large commercial or industrial projects benefit from fully automatic lines with higher speed, integrated TDF/TDC flanging and minimal manual handling. Smaller workshops or contractors focusing on renovation and residential projects may prioritize flexible, compact lines that can handle frequent changeovers without a big crew.

You should also consider the types of ducts you produce most often. If rectangular ducts with TDF flanges dominate your workload, investing in a line with strong notching, TDF forming and automatic folding makes sense. If you see growing demand for spiral ducts, it may be better to combine a simpler rectangular line with a separate spiral duct forming machine.

Labor, Skills and Maintenance Resources

An automatic duct line can dramatically reduce the number of operators needed per shift, but higher automation also requires staff who can handle programming, basic maintenance and troubleshooting. When comparing options, look at how user‑friendly the HMI is, whether the supplier offers training and remote support, and what kind of local service network is available.

For many B2B buyers, total cost of ownership—including downtime, spare parts and energy consumption—is more important than the initial price.

Where durmahvac Fits In

At durmahvac, we focus on ducted HVAC solutions that rely on clean, well‑sealed ductwork to deliver quiet, comfortable air distribution throughout the building. When our engineering team advises contractors or factory owners, we not only look at the ducted indoor units themselves, but also at how the ducts are produced. By matching the capacity of the automatic duct line with the project pipeline, we help partners avoid bottlenecks in fabrication and reduce rework caused by inaccurate or poorly finished ducts.

Conclusion

Understanding the components of an automatic duct line gives you a clear picture of how raw coil material is transformed into leak‑tight HVAC ducts with minimal manual work. By looking closely at each section—decoiler, leveling, notching, punching, cutting, folding, lock forming, flanging and control system—you can better evaluate competing offers and choose a configuration that truly matches your production needs.

If you are planning a new duct workshop or upgrading your existing facility to support more ducted AC projects, consider both the capacity of your automatic duct line and the performance of the ducted indoor units that will use those ducts.

- Download a checklist for specifying an automatic duct line for HVAC projects.

- Send project drawings to durmahvac for a combined duct line and ducted AC recommendation.

- Contact your sales team for a one‑on‑one consultation on how to modernize their duct production.