Rising labor costs, worker shortages, and compressed project timelines challenge B2B HVAC duct fabricators worldwide. This comprehensive guide breaks down auto duct lines versus semi-automatic setups across capacity, precision, costs, and real-world ROI, empowering windpipe-focused factories to choose wisely.

Core Concepts Explained

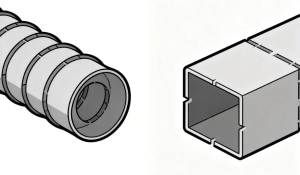

Auto duct lines represent the pinnacle of rectangular HVAC duct production, automating the entire workflow from decoiling to final bending with minimal human input. Semi-automatic lines, by contrast, link standalone machines where operators handle material transfers and setups between steps.

Auto Duct Line Breakdown

These systems process sheet metal coils through integrated stations including:

Decoiling and leveling for flat, tension-free stock.

Servo-controlled beading, punching, and notching for precise reinforcement.

High-speed shearing and lockforming (Pittsburgh or TDF flanges).

Orthogonal bending for ready-to-assemble ducts.

Ideal for high-volume shops producing standardized rectangular ducts, they deliver seamless operation via PLC controls and touchscreens.

Semi-Automatic Duct Line Overview

Built from modular machines like coil lines, shears, auto lines, lockformers, seam closers, and benders, these require skilled operators to stage materials and monitor each phase. They offer flexibility for custom jobs but introduce bottlenecks from manual handling and repositioning.

Common in smaller or startup workshops, they suit varied duct specs where full automation feels overkill.

Detailed Performance Comparison

Auto lines outperform in scaled production, slashing cycle times while boosting quality consistency critical for commercial HVAC installs.

Aspect | Auto Duct Line | Semi-Automatic Duct Line |

|---|---|---|

| Production Capacity | 20-40+ ducts/hour (std. sizes, continuous feed) durmahvac+1 | 8-20 ducts/hour (manual pacing limits throughput) blkma+1 |

| Duct Precision | ±0.5mm length/angle via CNC servos durmahvac | ±1-2mm; errors compound across transfers blkma |

| Labor Requirements | 1-2 operators/shift (monitoring + loading) predacnc | 4-6 workers (handling, setup, quality checks) smartbuy.alibaba |

| Initial Investment | $150K-$400K (Lines 3-5, full integration) durmahvac+1 | $50K-$150K (machine combo) smartbuy.alibaba |

| Floor Space Needs | 20-30m linear/U-shaped layout durmahvac | 30-50m² dispersed stations blkma |

| Maintenance | Centralized PLC/hydraulics (scheduled, remote diag.) durmahvac | Frequent per-machine tweaks blkma |

| Waste/Defect Rate | 2-5% (automated quality control) predacnc | 8-15% (human variability) smartbuy.alibaba |

Tailored Use Cases for Duct Fabricators

Align equipment with your order profile, workforce, and growth trajectory for maximum uptime.

High-Volume OEM/Export Factories

Stable, large-batch runs (e.g., 5,000+ ducts/year) demand Auto Duct Line 4 or 5. Expect 60% faster cycles and single-shift capacity rivaling multi-shift semi-auto, perfect for TDF/Pittsburgh-equipped models serving global HVAC giants.

Small-to-Medium Workshops

Intermittent orders under 2,000 ducts/year favor semi-automatic combos. Pair a basic coil line with shears and benders for flexibility without locking into high CapEx—ideal for regional contractors testing the market.

EPC/Construction Site Processing

Project spikes suit portable semi-auto for quick setups, but repeat contracts justify auto lines to cut on-site crews amid global labor crunches.

ROI Calculation Guide

Project payback with this formula:

Payback Period (months) = Equipment Cost / [(Annual Ducts × Avg. Profit/Duct Savings) – Operating Costs]

Example for 10,000 ducts/year at $5 profit boost/duct (labor + waste):

Auto Line ($250K): ~18 months.

Semi-Auto ($100K): Ongoing high labor erodes gains beyond 24 months.

Quick Self-Assessment Checklist:

Annual output >3,000 ducts? Labor costs rising? → Auto duct line.

Startup phase or custom jobs? Tight budget? → Semi-automatic.

Expanding to exports? Strict tolerances? → Auto Line 5.

Next Steps for Optimization

HVAC duct producers specializing in windpipe machines can source Auto Duct Lines 3-5 with plug-and-play integration for 1.0-1.35mm steel. Seek custom factory layouts and ROI simulators from trusted manufacturers for overseas-ready machines with full support.

FAQ

1. How do I decide whether to choose an auto duct line or a semi-automatic combination?

For square or rectangular duct production, the choice mainly depends on your production volume, labor cost, and growth plan. Higher, stable output and expensive labor favor an auto duct line, while low or fluctuating volumes with cheaper labor often justify a semi-automatic combination.

2. Is an auto duct line suitable for small workshops?

An auto duct line can be used in small workshops if there is consistent demand and a clear plan to scale duct output. Very small or project-based shops usually start with semi-automatic machines, then upgrade when manual handling becomes a bottleneck.

3. What materials and thicknesses can a typical auto duct line handle?

Most HVAC auto duct lines are designed for galvanized steel, aluminum, or similar metals in the 0.4–1.2 mm range, depending on the model. Higher-grade lines can support multiple coils and thickness selections for different pressure classes and duct sizes.

4. How does an auto duct line improve duct quality?

Because key operations—leveling, punching, notching, cutting, and forming—are CNC-controlled, an auto duct line keeps dimensional accuracy within tight tolerances and reduces human error. This leads to more consistent flanges, seams, and corner cuts, which improves air-tightness and reduces rework on site.

5. What is the typical capacity of an auto duct line?

Depending on configuration, an auto duct line can reach production speeds of around 20–30 meters per minute or complete most steps for straight duct sections in a single pass. Actual duct pieces per hour will vary with duct size mix, thickness, and operator scheduling.