Hydraulic duct elbow machines have become the backbone of modern HVAC fabrication. Unlike traditional manual methods, these machines deliver highly consistent elbows, minimize labor requirements, and improve workflow efficiency.

For example, a mid-size HVAC workshop using a DP-ELB-500 machine increased its daily elbow output by 30% while reducing operator load from three to one.

In this guide, we explore the working principles, key components, applications, specifications, and tips for selecting the right machine—so you can make informed decisions and optimize your HVAC fabrication operations.

What Is a Hydraulic Duct Elbow Machine?

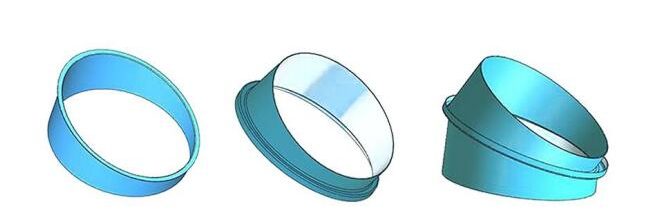

A hydraulic duct elbow machine is designed to bend sheet metal into precise round or rectangular duct elbows using controlled hydraulic pressure.

Key features include:

Adjustable dies for different angles and diameters

Hydraulic system for consistent forming pressure

Feeding and positioning units for precise alignment

PLC or foot-pedal controls for repeatable operation

Application Example:

Airports and hospitals often require high-volume, precise duct elbows to maintain airflow efficiency. Using a hydraulic elbow machine ensures each elbow meets design specifications with minimal rework.

Key Components Explained

1. Hydraulic System

Hydraulic pressure is applied gradually to bend sheet metal without causing stress cracks. Modern systems have pressure sensors and adjustable valves to maintain repeatability even with varying material thickness.

2. Forming Dies & Tooling

Dies determine the elbow shape. Interchangeable sets allow fabrication of multiple angles and diameters. High-precision dies reduce deformation and improve surface smoothness, which is critical in HVAC applications where airflow turbulence must be minimized.

3. Feeding & Positioning Unit

Accurate positioning reduces material waste and ensures consistent elbow geometry. Automated feeders can align sheets within ±0.5 mm tolerance, improving efficiency in batch production.

4. Control System

PLCs and digital controls let operators set hydraulic pressure, stroke, and cycle timing, achieving repeatable results without relying heavily on operator skill.

Tip: Use a slightly oversized die for thicker materials to reduce stress and ensure consistent forming.

How Hydraulic Duct Elbow Machines Work (Overview)

Step-by-step workflow:

| Step | Action | Key Points |

|---|---|---|

| 1 | Sheet loading | Galvanized, stainless, aluminum sheets |

| 2 | Alignment | Accurate positioning reduces forming errors |

| 3 | Hydraulic forming | Gradual pressure bends sheet into die shape |

| 4 | Release | Remove formed elbow without deforming |

| 5 | Inspection | Check angle, diameter, and surface finish |

For a detailed workflow, see How Does a Hydraulic Duct Elbow Machine Work.

Applications and Benefits

Hydraulic duct elbow machines are ideal for:

Commercial HVAC systems

Industrial air distribution

Airports, hospitals, and factories

Benefits:

Consistent quality reduces rework

Labor efficiency allows one operator to manage multiple machines

High repeatability supports batch production

Material efficiency reduces waste

Selecting the Right Machine

Key factors:

Material thickness – Thicker sheets need higher hydraulic pressure.

Duct diameter & elbow range – Ensure dies and hydraulic capacity fit your workflow.

Production volume – Small workshops may use semi-automatic; high-volume requires full automation.

Workshop layout – Consider space, power supply, and material handling.

Learn detailed selection criteria in How to Choose the Right Hydraulic Duct Elbow Machine.

Maintenance Tips

Monitor and replace hydraulic oil regularly

Inspect dies and tooling for wear

Clean and lubricate moving parts

Perform routine safety checks

Proper maintenance ensures consistent forming quality and extends machine life, minimizing downtime and operating costs.

Common Mistakes to Avoid

Choosing equipment based solely on price

Ignoring future production growth

Selecting a machine unsuitable for material thickness

Overlooking workshop space and workflow

Conclusion

Hydraulic duct elbow machines provide precision, efficiency, and consistent quality for HVAC duct fabrication. Understanding their components, workflow, applications, and maintenance ensures long-term operational success.

A structured approach to choosing the right hydraulic duct elbow machine ensures stability, productivity, and return on investment.

FAQ

What materials can the machine process?

Galvanized steel, stainless steel, aluminum

What elbow angles are supported?

30°, 45°, 60°, 90° (depends on tooling)

How fast can one machine produce elbows?

Typically 30–60 seconds per elbow, depending on thickness and automation

Is operator training required?

Basic training is sufficient; modern controls simplify operation