In modern HVAC duct manufacturing, efficiency and consistency are critical factors that directly affect project delivery and production costs. As duct workshops move from manual or semi-automatic processes toward higher automation, the Auto Duct Line has become a widely adopted solution for medium to high-volume production. As a mid-to-advanced solution, Auto Duct Line 5 belongs to the broader category of automatic duct lines used for continuous HVAC duct manufacturing.It offers a balanced combination of automation, flexibility, and output capacity without the complexity of fully customized production lines.

What Is Auto Duct Line 5?

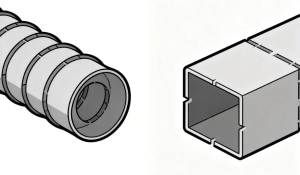

Auto Duct Line 5 is an integrated automatic duct production line designed for manufacturing rectangular HVAC ducts. Rather than performing a single task, it combines multiple forming operations into a continuous workflow, reducing manual handling and improving dimensional consistency.

Compared with basic duct production setups, Auto Duct Line 5 is positioned as a mid-to-advanced solution. It is commonly used by HVAC manufacturers who require stable daily output, repeatable quality, and reduced labor dependency, but who may not yet need a fully customized or ultra-high-capacity system.

Typical Configuration of Auto Duct Line 5

The exact configuration can vary depending on manufacturer and project requirements, but its functional structure generally follows a standardized layout focused on process continuity.

Feeding, Cutting, and Grooving Section

The production process typically begins with automatic coil feeding and straightening, followed by precise cutting to length. Integrated duct grooving at this stage ensures precise edge preparation before downstream forming and locking operations. Grooving units are integrated at this stage to prepare duct edges for subsequent forming and connection processes. This early integration of edge preparation helps maintain alignment and reduces rework later in the line.

Forming and Locking Units

After cutting and grooving, the sheet metal passes through forming units that shape duct profiles and connection features. These may include flange forming, folding, or seam preparation modules depending on the required duct design. Locking or seam closing units then secure the formed edges, ensuring structural stability and airtight performance.

Control System and Line Integration

A centralized control system coordinates each station along the line. By synchronizing feeding speed, forming operations, and material transfer, the system maintains stable production flow. Operators can adjust parameters such as duct length, forming sequence, and production batches without interrupting the overall process.

How Auto Duct Line 5 Works in Production

In daily operation, Auto Duct Line 5 functions as a continuous manufacturing system rather than a collection of independent machines. Once production parameters are set, sheet metal moves through the line with minimal manual intervention. Each forming stage builds upon the previous one, allowing ducts to be produced with consistent geometry and repeatable quality.

This integrated workflow reduces handling time, minimizes measurement errors, and improves overall production stability, especially during extended operating shifts.

Production Capacity and Output Range

Production capacity is influenced by several practical factors rather than a single theoretical output value. Material thickness, duct size range, forming complexity, and operator setup practices all affect real-world performance.

In typical HVAC manufacturing environments, Auto Duct Line 5 is suitable for continuous production across standard rectangular duct sizes. It is commonly selected by workshops aiming to support steady commercial project demand or industrial ventilation contracts without bottlenecks.

Auto Duct Line 5 vs Other Duct Production Lines

Auto Duct Line 5 occupies a middle ground between basic automatic duct lines and highly customized production systems. Compared with simpler lines, it offers greater process integration and reduced reliance on manual forming. Compared with advanced multi-line systems, it maintains flexibility and lower operational complexity.

This positioning makes it especially suitable for manufacturers seeking to upgrade production capability while maintaining manageable investment and operational requirements.

Applications in HVAC Duct Manufacturing

Auto Duct Line 5 is widely used in commercial HVAC projects, industrial ventilation systems, and medium to large duct fabrication workshops. Its balanced automation level allows it to handle both standardized production runs and moderate variations in duct specifications.

Key Considerations Before Choosing Auto Duct Line 5

Before selecting Auto Duct Line, manufacturers should evaluate expected production volume, duct design requirements, and long-term automation plans. Consideration should also be given to factory layout, operator training, and potential future expansion.

Matching the line configuration to actual production needs ensures optimal return on investment and long-term production stability.

Conclusion: When Auto Duct Line 5 Is the Right Choice

Auto Duct Line 5 is designed for manufacturers who require reliable, efficient, and scalable HVAC duct production. By integrating multiple forming processes into a coordinated system, it supports consistent output while maintaining operational flexibility. For workshops planning to move beyond basic automation without overextending complexity, Auto Duct Line 5 represents a practical and well-balanced solution.

FAQs About Auto Duct Line 5

It is suitable for medium to high-output HVAC duct manufacturers seeking consistent quality and reduced labor input.

It is highly automated but still allows operator control and adjustment, offering a balance between automation and flexibility.

Yes, configurations can be adapted based on duct size range, forming requirements, and production goals.