CNC PLASMA CUTTING MACHINE

首页 » CNC PLASMA CUTTING MACHINE

Rectangular Duct Making Machine

- CNC Plasma Cutting Machine

- Contact Us

Brand: DURMAPRESS

Function

- Main Function: CNC plasma cutting machine is used for automatic lofting and cutting of deformed workpieces.

- Advanced Software: Equipped with the latest CAM-DUCT PM 2000 software, integrating technology, data processing, and management.

- Advantages: Offers convenient, accurate, and practical operation.

- Stable Performance: Uses a dedicated control system to ensure more stable functionality.

- Automation: Can automatically generate drawings and output processing procedures.

Robust Structure & Precision

Welded thickened square tube frame combined with top-brand guide rail ensures high speed and cutting accuracy.

Advanced Plasma System

Equipped with Hypertherm power supply and high-sensitivity arc pressure adjuster for automatic distance control between torch and material.

Smart Control System

Uses STARFIRE control system and FastCAM software for efficient material usage, large storage capacity, and easy processing.

Efficient Cooling Head

The cutting head includes a cooling system to reduce burrs and residue on the material surface.

High-Precision Drive System

Stepper motors with high-precision rack and pinion ensure smooth, quiet, and accurate movement.

Wide Software Compatibility

Compatible with various design software including Ucancam, Type 3, and Artcut.

Function & Application

The CNC plasma cutting machine is mainly used for automatically lofting and cutting deformed sheet metal, especially for HVAC ventilation ducts. It supports galvanized sheet (0.4–4 mm) and stainless steel (up to 2 mm).

Software & Operation

Equipped with the latest AutoDesk CAM-DUCT software, the machine simplifies the process by allowing users to select duct shapes, input dimensions, and automatically generate unfolded views and cutting instructions. It is convenient, accurate, and easy to learn.

Control System & Hardware

The machine features a 10-inch vertical touchscreen, PM200 control system, and a HUAYUAN generator (Hypertherm optional). It includes the main machine, generator, and CNC control system for stable and efficient operation.

Cutting Stability & Features

With a unique height adjustment device, it avoids sticking issues between the cutting head and sheet metal. Rolling friction improves stability and greatly enhances cutting speed. It also comes with specialized air duct expansion software for drawing generation and processing output.

After-sales Service

Durmapress provides remote video guidance from skilled technicians and offers optional overseas engineer service to ensure proper operation and support.

1. Processor: using industrial grade ARM processing chip;

2. Display: 7-inch color LCD, 800*480;

3. Input\Output: The system provides 16 channels of photoelectric isolation input and 16 channels of photoelectric isolation output;

4. Number of linkage axes: 2 axes, which can be expanded to 3 linkage axes;

5. Maximum speed: not less than 24 m/min;

6. Pulse equivalent: flexible adjustment;

7. Storage space: 4G large user program storage capacity, unlimited processing programs;

8. Chassis size: 298×202×65(mm);

9. Working temperature: 0℃~+40℃;

Storage temperature: -20℃~+60℃;

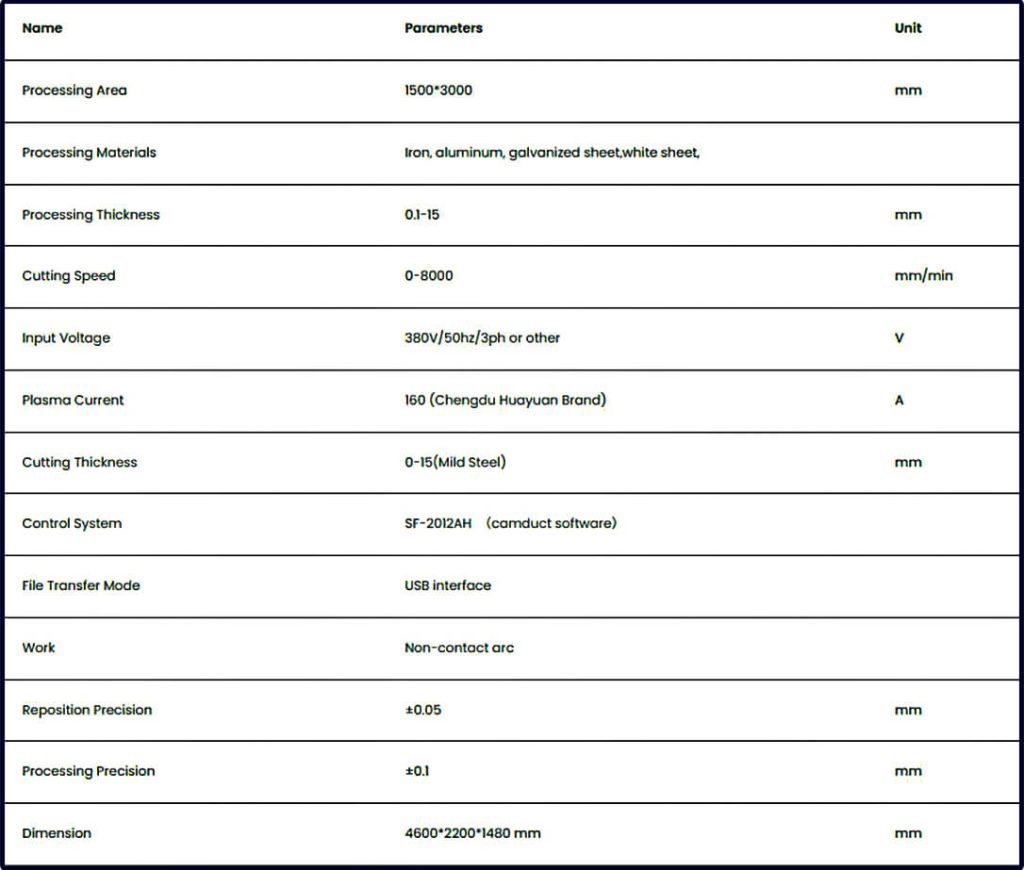

- Technical Data

- Production Details

.jpg)

Machine Frame

The frame is integrally welded and annealed, and the main frame is welded with medium-sized steel pipes; the rail bottom plate is precisely processed by a planer, with high strength, good precision and no deformation.

CNC control System

The CNC control system ensures high precision, easy operation, and enhanced automation for efficient and accurate plasma cutting.

.jpg)

.jpg)

Water chiller system

The chiller system maintains optimal temperature for the plasma cutting machine, preventing overheating of the torch and power supply, ensuring consistent performance and extending equipment lifespan.

Plasma Power

The plasma power supply delivers stable and powerful arc performance, ensuring fast, precise, and clean cuts on various metals.

.jpg)

.jpg)

Plasma cutting torch

The plasma cutting torch provides precise control of the cutting process, delivering clean, accurate cuts while minimizing slag and ensuring high-quality results on various materials.

air compressor

Provides a steady source of compressed air to support the gas supply in the plasma cutting process.

.jpg)

.jpg)

Final Products

Choose advanced mechanical design technology, the motor and reducer are integrated to reduce the loss of transmission power.

- Plasma Power Optional :

Hyptherm Power

Huayuan Power

- Why Choose Us

Industry Experts

Professional HVAC Duct Machines Manufacturer

Perfect After-sales

24-hour after-sales response service

Engineer Overseas Service

Our engineers provide 24/7 on-site technical support

- Frequently Asked Questions

- You can choose the shipping company on your own. Or use our forwarder, we will quote you the CIF price.

- If less than one container,we will choose LCL (less container load), it will be cost-efficiency. If you purchase two and above, we will use 20″, 40″ or HQ container according to the machines size.

DURMAPRESS is a mature brand in China. We have CE, ISO and SGS certification to prove our quality. We welcome your visit, seeing is believing.

- T/T (30% advance payment, and 70% balance paid one week before shipment)

- L/C (100% L/C at sight), this should be negotiated first.

We always prepare stock for our clients. Contact us to learn more details.

Normally 15 days.

- Write Us

.jpg)