Automatic duct line failures cost HVAC fabricators thousands in lost production every month. A single decoiler jam can halt an entire shift, while TDF flange defects generate scrap that eats into margins. This guide covers the 10 most common automatic duct line problems with immediate fixes and prevention strategies, helping workshop owners cut downtime by 50%+.

Material Feeding Failures (40% of Service Calls)

Decoiler Jamming / Coil Slipping

Problem: Sheet metal bunches up at decoiler exit, line stops every 5-10 panels

Causes:

Insufficient mandrel expansion (wrong coil ID)

No hydraulic hold-down arm or weak pressure

Excessive coil tension or lubrication issues

Immediate Fix (15 min):

Stop line, release coil tension

Verify mandrel claws grip inner diameter properly

Adjust hydraulic hold-down pressure to 2-3 bar

Clean pinch rollers, apply light lubricant

Prevention: Weekly mandrel inspection, create coil spec checklist (ID, OD, weight limits)

Leveler Misalignment / Wavy Sheets

Problem: Output sheet waves ±3mm, causes punching errors downstream

Causes: Worn leveling rollers, loose frame mounting bolts

Immediate Fix (30 min):

Check all 12 leveling roller gaps (0.4-0.6mm typical)

Shim leveling frame if table uneven >1mm

Tighten 24 frame mounting bolts to spec (85Nm)

Root Cause Check: Place straight edge across leveled sheet. If gap >2mm at ends, replace top roller set (typical life: 18 months heavy use).

Precision Processing Failures

Notching/Punching Position Errors

Problem: Holes 3-5mm off position, TDF corners don’t match

Causes: Servo encoder drift, loose servo motor coupling

Fix Sequence:

- PLC → Zero Return All Axes (takes 8 min)

- Check punching die mounting bolts (4x M12, 65Nm)

- Verify X/Y encoder wheels are clean, no metal shavings

- Test cut 1 sample panel per program

Pro Tip: Run daily “test notch” program (3 simple rectangles) before production.

Cutting Length Inaccuracy (±3mm vs spec ±0.5mm)

Problem: Short/over cuts ruin diagonal tolerance

Causes: Dirty encoder wheel, flying shear timing drift

Fix:

Clean encoder wheel with isopropyl alcohol

Reset shear trigger point: Measure 10 cuts, average error

Adjust PLC parameter S-105 (shear delay) by average/1000 sec

Verify hydraulic pressure stable 120-140 bar

Forming & Assembly Failures (Top Scrap Generators)

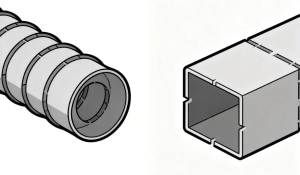

TDF Flange Forming Defects

CRACKED FLANGE (most common)

Cause: Roller gap too tight OR material >1.2mm thick

Fix: Loosen gap 0.1mm increments, verify material cert

INCOMPLETE ROLL (weak flange)

Cause: Roller wear OR low hydraulic pressure

Fix: Check forming ram pressure (180 bar typical)

Replace worn roll sets (check every 5000m processed)

Visual Check: Good TDF flange has smooth 25mm leg, no cracks, uniform thickness.

Pittsburgh Lock Seam Failure

Problem: Seam won’t zip closed, leaks at joints

Causes:

Dull forming rolls (most common)

Insufficient V-notch depth from earlier station

Wrong material thickness for roll setting

Fix Priority:

Measure V-notch depth (should be 8-10mm for 1.0mm GI)

Polish forming rolls with 400 grit (DIY fix)

Adjust entry guide to ensure square edge feed

Control System & Automation Issues

PLC Communication Drops (“E-301” Error)

Symptoms: Random station stops, restarts OK after power cycle

Causes: EMI interference, loose control cables

Fix Checklist:

□ Separate power/signal cables (>300mm spacing)

□ Check 24VDC supply ripple (<0.5V)

□ Tighten all DB25/37 connectors

□ Add ferrite cores on servo cables

Prevention: Annual cable inspection, UPS backup.

Nesting Software Glitches (20% Material Waste)

Symptoms: Impossible part layouts, overlapping notches

Fix:

Clear program cache (PLC → Maintenance → Reset)

Limit parts per program to 50 max

Verify DXF import scale (1:1)

Backup working programs weekly to USB

Mechanical Wear Issues

Hydraulic System Problems

Symptoms: Slow TDF forming, weak cutting power

Daily Check (5 min):

- Oil level: between marks (cold)

- Oil temp: 40-60°C operating

- Filter pressure diff: <1.5 bar

- No metal particles on sight glass

Service Schedule: Oil/filter change every 2000 hours or 6 months.

Conveyor Slippage / Panel Drops

Fix:

- Chain drive: Adjust tension (15-20mm deflection)

- Belt drive: Check belt tension (finger pressure test)

- Clean all rollers weekly – metal dust kills bearings

Ultimate Duct Line Maintenance Checklist

| Frequency | Tasks | Time |

|---|---|---|

| Daily | Visual inspection, lube points, debris clearance | 5 min |

| Weekly | Encoder clean, hydraulic check, zero calibration | 30 min |

| Monthly | Full alignment, roller gap check | 2 hr |

| Quarterly | Oil/filter service, wear parts inspection | 4 hr |

When to Call durmahvac Technical Support

DIY Limit: 3+ failures same station OR repeat issues after fixes

Immediate Dispatch Triggers:

PLC will not boot

Servo drive alarms (F-series errors)

Custom tooling damage