In HVAC duct manufacturing, not every duct section is straight or standardized. Changes in airflow direction, space constraints, and installation requirements often demand controlled bending rather than simple cutting or folding. This is where a duct bending machine becomes relevant. Instead of forcing installers to adapt rigid duct sections on site, bending allows manufacturers to deliver ducts that fit complex layouts with higher accuracy and consistency.

This article explains what a duct bending machine is, where it is used, how the bending process works, and which specifications matter most when selecting equipment for HVAC duct production.

What Is a Duct Bending Machine?

A duct bending machine is a piece of forming equipment designed to bend sheet metal ducts to specific angles or radii without compromising structural integrity. Unlike cutting or grooving operations that focus on edge preparation, bending reshapes the duct body itself to achieve directional changes or custom profiles.

In HVAC manufacturing, duct bending equipment is typically used after cutting and edge-forming processes. It complements other forming operations by enabling precise shape control while maintaining smooth airflow paths inside the duct.While bending reshapes the duct body, edge preparation processes such as duct grooving focus on creating reliable mechanical joints along the duct edges.

Where Duct Bending Machines Are Used in HVAC Manufacturing

Duct bending machines are most commonly applied in situations where standard straight duct sections are not sufficient. Typical use cases include:

- Non-linear duct routes required by building layouts

- Offset sections to avoid structural obstacles

- Transition areas where airflow direction must change smoothly

In these scenarios, bending provides a cleaner and more predictable solution than assembling multiple straight sections with connectors.

How the Duct Bending Process Works

Although machine designs vary, the duct bending process follows a similar mechanical principle across most systems.

Sheet Metal Positioning and Bending

The duct or sheet metal section is positioned against forming tools or bending dies. Controlled force is applied gradually, allowing the material to deform to the required angle without cracking or excessive thinning. Proper alignment during this stage is essential for maintaining dimensional accuracy.

Angle Control and Repeatability

Consistent bending angles are critical in HVAC production, especially when multiple duct sections must align during installation. Modern duct bending machines use mechanical stops, hydraulic control, or CNC systems to ensure repeatable results across production batches.

Common Types of Duct Bending Machines

Different production environments require different bending solutions.

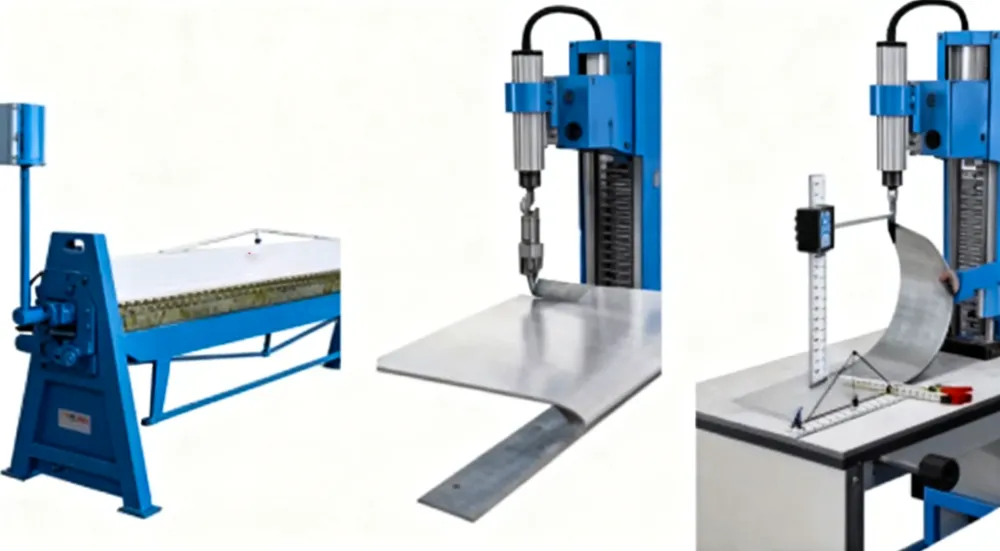

Manual duct bending machines are typically used in small workshops or for low-volume production. They offer flexibility but rely heavily on operator skill.

Hydraulic or motorized bending machines provide greater force and stability, making them suitable for thicker materials and higher output levels. These machines reduce operator effort and improve consistency.

CNC-controlled bending equipment is used in advanced manufacturing settings where precision and repeatability are critical. These systems allow bending parameters to be programmed and adjusted digitally, supporting complex duct geometries.

Key Specifications to Consider

When evaluating a duct bending machine, specifications should be matched to actual production needs rather than maximum theoretical capacity. Important factors include:

- Material thickness range supported by the machine

- Maximum bending angle achievable without material damage

- Duct size capacity, including width and height limitations

- Control accuracy, which affects repeatability and fit during installation

Balancing these specifications helps ensure stable performance without unnecessary cost.

Duct Bending Machine vs Other Duct Forming Equipment

A duct bending machine serves a different purpose compared to other forming equipment. Roll forming systems are optimized for creating continuous profiles, while panel bending focuses on flat sheet manipulation. For seam-based rectangular ducts, RAS seam closing is commonly applied after forming to lock and reinforce folded seams before final assembly. Bending equipment, by contrast, is best suited for shaping already-formed duct sections where directional control is required.

Understanding these differences helps manufacturers choose the right combination of machines for their production workflow.

Integration of Duct Bending Machines in Production Lines

In smaller facilities, duct bending machines often operate as standalone workstations. In higher-volume environments, bending can be integrated into semi-automated or automated duct production lines. Integration improves material flow, reduces handling time, and supports consistent output quality.

When combined with cutting, grooving, and flange forming operations, duct bending becomes part of a coordinated manufacturing process rather than an isolated task.

Conclusion: When a Duct Bending Machine Makes Sense

A duct bending machine is not required for every HVAC duct application, but it becomes essential when precision, flexibility, and installation efficiency are priorities. By understanding its use cases and key specifications, manufacturers can determine when bending equipment adds real value to their duct production process.

FAQs About Duct Bending Machines

No. Many standard duct installations use straight sections. Bending is primarily required for customized layouts or space-constrained projects.

Yes. Modern bending machines can be automated using hydraulic or CNC control, especially when integrated into production lines.

Galvanized steel is the most common material, but aluminum and stainless steel can also be bent with appropriate machine settings.