HVAC duct manufacturing is not just about cutting sheet metal into shape. To achieve accurate airflow, reliable connections, and consistent assembly, ducts must go through a series of forming operations. This is where a duct forming machine plays a central role. Rather than being a single-purpose device, duct forming machines represent a group of forming equipment designed to shape, reinforce, and prepare sheet metal ducts for installation.

In this article, we explain what a duct forming machine is, its core functions, the main machine types used in HVAC production, and how these machines work together in modern duct manufacturing lines.

-转换自-jpg-1024x576.webp)

What Is a Duct Forming Machine?

A duct forming machine is equipment used to shape flat sheet metal into functional HVAC duct components. Forming refers to mechanical processes that change the geometry of the metal without cutting it into separate parts. These processes allow ducts to gain structural strength, defined profiles, and connection features required for assembly.

Unlike cutting or welding equipment, duct forming machines focus on edge preparation, profile shaping, and dimensional consistency. They are essential in HVAC manufacturing because airflow performance, sealing quality, and installation efficiency all depend on precise duct geometry.

Core Functions of Duct Forming Machines

Duct forming machines serve several fundamental purposes in HVAC production. First, they shape sheet metal into standardized duct profiles, ensuring uniform dimensions across batches. Second, they prepare duct edges for connection by forming grooves, flanges, or seams that allow secure joining. Third, they improve structural rigidity, enabling ducts to maintain shape during transport, installation, and long-term operation.

Together, these functions transform raw sheet metal into duct sections that are ready for assembly, sealing, and installation in ventilation systems.

Main Types of Duct Forming Machines

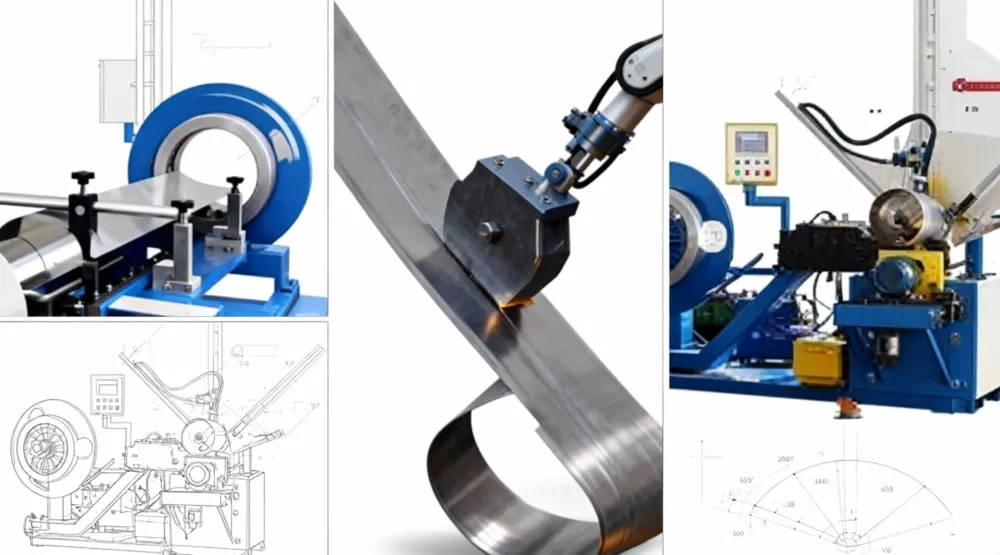

Although the term duct forming machine is often used broadly, HVAC production typically relies on several specialized forming machines, each responsible for a specific operation.

Duct Grooving and Edge Forming Machines

Grooving machines create precise grooves along duct edges. These grooves are critical for enabling flange forming, seam locking, and airtight assembly. Edge forming equipment ensures that duct connections remain consistent and compatible with downstream forming processes.

Flange Forming Machines

Flange forming machines shape reinforced edges along rectangular ducts. These flanges provide strong mechanical connections between duct sections and allow the use of gaskets or sealants to prevent air leakage. Flange forming is especially common in commercial and industrial HVAC projects where duct strength and sealing reliability are critical.

Duct Bending Machines

Duct bending machines are used to form angles, offsets, and directional changes without cutting and rewelding the duct. By bending the sheet metal directly, these machines improve airflow continuity and reduce leakage risks caused by excessive joints.

Seam Closing and Locking Machines

Seam closing machines, including RAS seam closing equipment, lock duct seams by mechanically folding and compressing formed edges. This process reinforces the duct structure and ensures long-term stability under air pressure.

How Duct Forming Machines Work Together in Manufacturing

In practical HVAC production, duct forming machines rarely operate in isolation. A typical manufacturing workflow begins with cutting and grooving, followed by flange forming or bending, and ends with seam closing and final assembly. Each forming operation builds on the previous one, creating a controlled and repeatable process.

This system-based approach allows manufacturers to maintain consistent quality while adapting production to different duct sizes, materials, and project requirements.

Duct Forming Machine vs Automatic Duct Line

A duct forming machine usually refers to a single piece of equipment performing one forming task. An automatic duct line, by contrast, integrates multiple forming machines into a continuous production system. Automatic duct lines combine feeding, cutting, grooving, forming, and locking into a single workflow.

Standalone duct forming machines are suitable for small to medium production volumes or customized projects. Automatic duct lines are preferred for high-volume manufacturing where speed, consistency, and labor efficiency are priorities.

Key Considerations When Choosing Duct Forming Equipment

Selecting duct forming equipment depends on several factors, including production capacity, duct type, and automation level. Manufacturers should consider the range of duct sizes required, material thickness, and whether future expansion toward automated production is planned. Matching forming machines to actual production needs helps avoid unnecessary complexity while ensuring reliable output.

Applications of Duct Forming Machines in HVAC Manufacturing

Duct forming machines are widely used in commercial HVAC systems, industrial ventilation projects, and custom duct fabrication workshops. From office buildings to factories and large infrastructure projects, these machines support efficient duct production across a wide range of applications.

Conclusion: The Role of Duct Forming Machines in Modern HVAC Production

A duct forming machine is not a single tool but a category of essential forming equipment in HVAC manufacturing. By shaping, reinforcing, and preparing ducts for assembly, these machines form the backbone of reliable duct production. Understanding their functions and how they work together helps manufacturers build efficient, scalable, and high-quality HVAC duct systems.

FAQs About Duct Forming Machines

It shapes sheet metal into duct profiles and prepares edges for secure assembly.

It can be manual, semi-automatic, or fully automated depending on the equipment and production line.

No. HVAC manufacturing typically requires multiple forming machines working together.