In modern HVAC duct manufacturing, consistent edge quality is essential for reliable duct connections and efficient installation. As production volumes increase and automation becomes standard, the duct grooving machine has become a key piece of equipment in rectangular duct fabrication. It ensures precise, repeatable grooves along duct edges, supporting both standalone production and fully automated duct lines.

This article explains what a duct grooving machine is, how it works, its main components and types, and where it is applied in HVAC manufacturing. It is written for engineers, factory managers, and equipment buyers who want a clear technical understanding rather than a sales pitch.

What Is a Duct Grooving Machine?

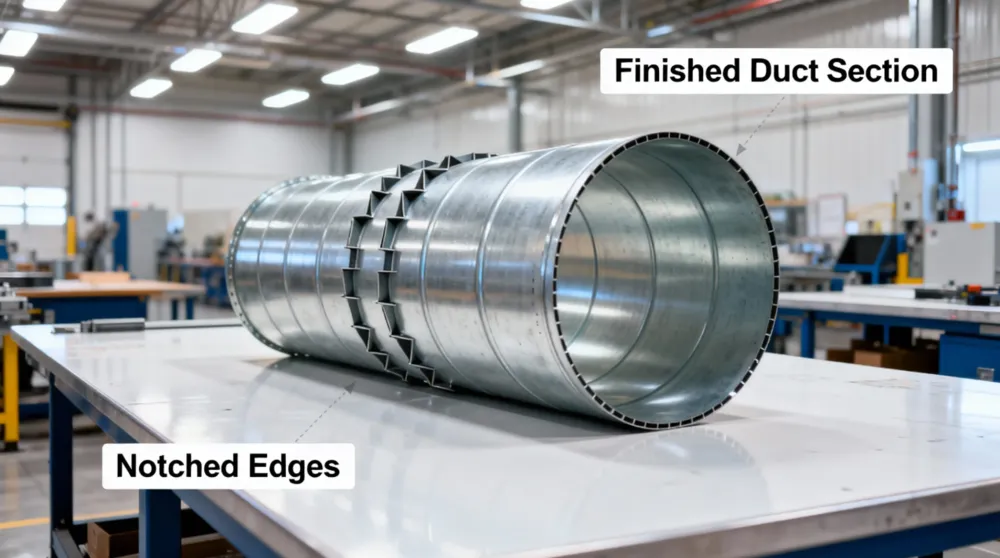

A duct grooving machine is a forming machine designed to create uniform grooves along the edges of rectangular HVAC ducts. These grooves allow ducts to be connected securely with flanges or frames, improving structural strength and sealing performance.

Compared with manual grooving or improvised forming methods, a dedicated duct grooving machine delivers consistent groove geometry across large production batches. This consistency is especially important in standardized HVAC projects and automated manufacturing environments.

How a Duct Grooving Machine Works

To better understand the machine itself, it is helpful to first review the duct grooving process, which explains why precise groove geometry is critical in HVAC duct manufacturing.The working principle of a duct grooving machine is based on controlled forming pressure and precise alignment. While designs vary, the basic process follows the same logic.

Material Feeding and Alignment

Flat sheet metal or pre-formed duct sections are fed into the machine through a guided feeding system. Accurate alignment ensures that grooves are formed at the correct position along the duct edge, preventing deviation that could affect assembly quality.

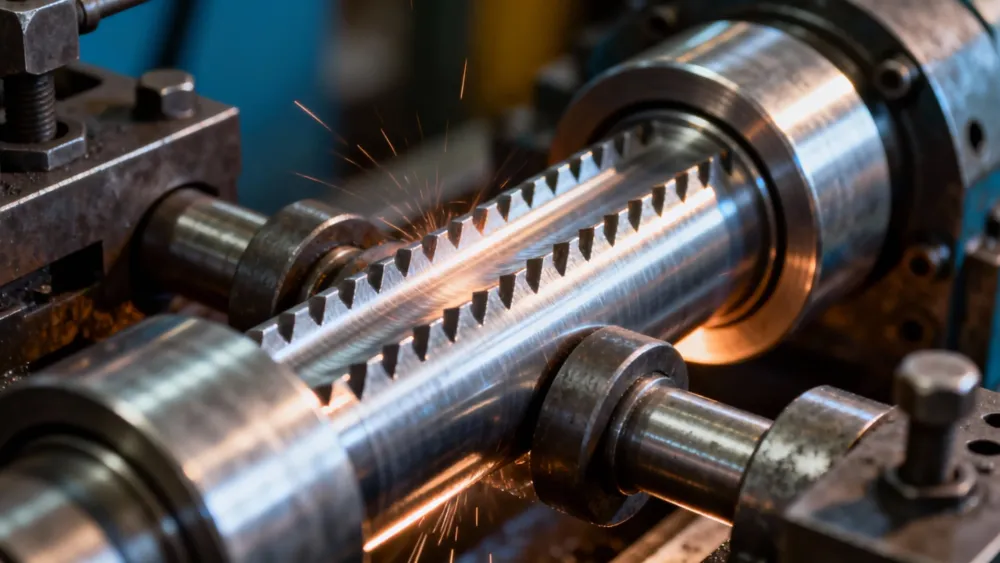

Groove Forming Mechanism

As the duct edge passes through the grooving station, forming rollers press the metal to create a continuous groove. The rollers are designed to maintain stable contact with the material, ensuring smooth groove formation without tearing or deformation.

Depth and Profile Adjustment

Groove depth and profile are adjustable to suit different duct specifications. Precise control of these parameters allows the machine to handle various duct sizes and material thicknesses while maintaining consistent results.

Main Components of a Duct Grooving Machine

Understanding the main components helps explain why these machines deliver stable and repeatable performance.

Grooving Rollers and Tooling

The rollers are the core forming elements. Their profile determines the groove shape, while material quality affects durability and surface finish.

Drive and Control System

The drive system powers the forming rollers and feeding mechanism. In advanced models, adjustable speed and synchronized controls improve accuracy and production efficiency.

Frame Structure and Stability

A rigid frame minimizes vibration during operation. Structural stability is essential to maintain groove consistency, especially in continuous production.

Types of Duct Grooving Machines

Different production setups require different machine configurations.

Standalone Duct Grooving Machines

Standalone machines operate independently and are commonly used in small to medium-sized HVAC workshops. They offer flexibility and are suitable for batch production or customized duct fabrication.

Integrated Grooving Units in Automatic Duct Lines

In high-volume factories, the duct grooving machine is often integrated into an automatic duct line, where forming, grooving, and cutting are synchronized for continuous production.In high-capacity factories, grooving units are often integrated directly into an automatic duct line. This integration allows grooving to be synchronized with forming, bending, and cutting processes, enabling continuous and highly efficient production.

Applications of Duct Grooving Machines in HVAC Manufacturing

Duct grooving machines are widely used across HVAC manufacturing scenarios, including:

- Rectangular duct production for commercial buildings

- Industrial HVAC systems requiring standardized duct connections

- High-volume duct fabrication lines supplying large construction projects

Their ability to deliver consistent groove quality makes them suitable for both standard and customized HVAC duct systems.

Duct Grooving Machine vs Other Duct Forming Equipment

While duct grooving machines focus on edge preparation, other equipment addresses different forming needs.

Duct Grooving Machine vs Flange Forming Machine

A flange forming machine creates flanges directly on the duct edge, whereas a duct grooving machine prepares the edge for connection with separate flange components. Grooving machines offer greater flexibility in automated production environments.Unlike a flange forming machine, which directly forms flanges on duct edges, a duct grooving machine prepares the edge for standardized flange assembly.

Duct Grooving Machine vs Lock Seam Formers

Lock seam formers, such as those used for Pittsburgh seams, are more common in manual or semi-automatic fabrication. Duct grooving machines provide higher consistency and are better suited for standardized, automated HVAC duct manufacturing.Traditional seam formers, such as RAS seam closing machines, are more common in manual duct fabrication, while duct grooving machines are optimized for automated production.

Integration of Duct Grooving Machines in Automatic Duct Lines

In a complete HVAC duct making machine system, the duct grooving machine typically operates after forming and before seam closing or flange installation. Its modular design allows it to be added or removed depending on production requirements.

By integrating grooving into an automatic duct line, manufacturers can reduce manual handling, improve throughput, and achieve more uniform product quality.

How to Choose a Duct Grooving Machine

When selecting a duct grooving machine, manufacturers should consider:

- Required production capacity and line speed

- Compatible duct sizes and material thickness

- Whether integration into an automatic duct line is needed

- Long-term stability and ease of adjustment

Choosing the right configuration ensures that the machine supports both current production and future expansion.

Conclusion: The Role of Duct Grooving Machines in Modern HVAC Production

As HVAC duct manufacturing continues to evolve toward automation and standardization, the duct grooving machine plays an increasingly important role. By delivering precise, repeatable grooves and integrating seamlessly into automatic duct lines, it supports higher efficiency, consistent quality, and scalable production.

For manufacturers evaluating HVAC duct making machines, understanding how a duct grooving machine works provides valuable insight into overall production capability and long-term manufacturing performance.

FAQs About Duct Grooving Machines

Yes. Most duct grooving machines allow adjustment of groove position and depth to accommodate various duct dimensions.

While not mandatory for every configuration, duct grooving machines are commonly integrated into automatic duct lines to ensure standardized connections and high production efficiency.

Common materials include galvanized steel, stainless steel, and aluminum, all of which are suitable for controlled grooving processes.