ELECTRICAL SHEARING MACHINE

首页 » ELECTRICAL SHEARING MACHINE

Rectangular Duct Making Machine

- Electrical Shearing Machine

- Contact Us

Brand: DURMAPRESS

Function

- The whole Electric Shearing Machine body uses the integrally weld structure, ensuring the high strength and good rigidity of the machine.

- The machine hasn't the clutch and the flywheel. It shears the sheet-metal directly drived by the magnetic brake motor. This reduces the idle time of the motor and saves the energy.

- Shearing blade uses 6Cr2Si material, ensuring the good performance and long performance life.

- The structure of the machine is simple, easy operation and low consumption.

Structure & Drive:

All-steel welded body with gate-type transmission, integrated motor and cycloidal pinwheel reducer, chain drive, and self-braking system.

Efficiency:

No power consumption without shearing; simple structure, easy to operate, and energy-saving.

Material Capacity:

Suitable for shearing 0.1–4 mm steel plates.

Blade Quality:

Uses durable 6CrW2Si high-alloy steel blade.

Applications:

Widely used in metal sheet processing industries such as metallurgy, machinery, hardware, motors, and auto maintenance.

Structure: The electric shearing machine adopts an integral steel welded structure, which is durable and highly reliable.

Function: It adopts chain drive and the gate knife shearing principle, and can cut metal plates with a thickness of less than 3 mm.

Energy saving: The motor has its own brake and no power consumption when not shearing.

Adjustability: The plate cutting width can be adjusted by the back gauge to ensure precise operation.

Integration with HVAC system: The electric shearing machine can be used in conjunction with other HVAC duct forming machines to complete the complete duct production, including: TDF flange forming machine, pneumatic TDF plate folding machine, slotting machine, edge locking forming machine, square duct edge sealing machine, and buckle cutting machine.

Customization: We provide a full range of customized models to meet the needs of different customers and actual operating environments.

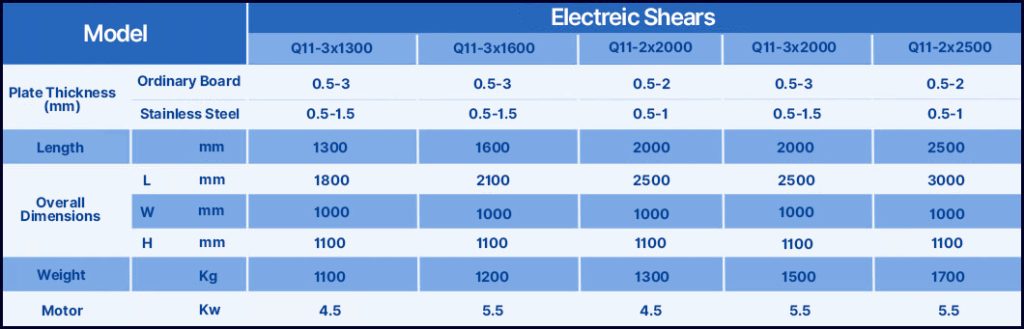

- Technical Data

- Why Choose Us

Industry Experts

Professional HVAC Duct Machines Manufacturer

Perfect After-sales

24-hour after-sales response service

Engineer Overseas Service

Our engineers provide 24/7 on-site technical support

- Frequently Asked Questions

- You can choose the shipping company on your own. Or use our forwarder, we will quote you the CIF price.

- If less than one container,we will choose LCL (less container load), it will be cost-efficiency. If you purchase two and above, we will use 20″, 40″ or HQ container according to the machines size.

DURMAPRESS is a mature brand in China. We have CE, ISO and SGS certification to prove our quality. We welcome your visit, seeing is believing.

- T/T (30% advance payment, and 70% balance paid one week before shipment)

- L/C (100% L/C at sight), this should be negotiated first.

We always prepare stock for our clients. Contact us to learn more details.

Normally 15 days.

- Write Us