In HVAC duct manufacturing, factory efficiency is not defined by speed alone. It is determined by how smoothly materials move through production, how consistently quality is maintained, and how predictable output remains under project pressure. As production demands increase, many factories find that traditional duct fabrication methods struggle to deliver stable performance. This is where automatic duct lines play a critical role.

Automatic duct lines are designed to transform fragmented duct production into a coordinated, continuous workflow. By integrating multiple fabrication processes into a single system, they directly address the most common efficiency bottlenecks in HVAC factories.

Why Factory Efficiency Matters in HVAC Duct Manufacturing

HVAC projects are typically driven by strict timelines, fluctuating workloads, and standardized duct specifications. When duct production becomes a bottleneck, delays quickly cascade into installation and commissioning phases.

Factory efficiency affects more than daily output. It influences labor allocation, material utilization, delivery reliability, and long-term competitiveness. A production line that operates inconsistently may appear productive during peak hours but ultimately increases rework, overtime, and scheduling uncertainty.

As HVAC systems grow larger and more complex, manufacturers need production methods that deliver stable, repeatable results rather than short bursts of speed.

What Limits Efficiency in Traditional Duct Production

Conventional duct fabrication often relies on multiple standalone machines arranged around a workshop. While this setup offers flexibility, it introduces several efficiency constraints.

Material must be manually transferred between cutting, forming, and locking stations. Each transfer increases handling time and creates opportunities for misalignment or damage. Production speed becomes dependent on individual operators rather than a coordinated process.

In addition, differences in machine cycle times often cause workflow interruptions. One station may finish early while another becomes a bottleneck, leading to idle time and inconsistent output. Quality control is also more variable, as manual operations introduce differences in edge preparation and seam locking.

These factors collectively reduce the overall efficiency of HVAC duct manufacturing.

How Automatic Duct Lines Improve Production Efficiency

Automatic duct lines improve factory efficiency by redesigning how work flows through production rather than simply accelerating individual steps.

Continuous and Integrated Workflow

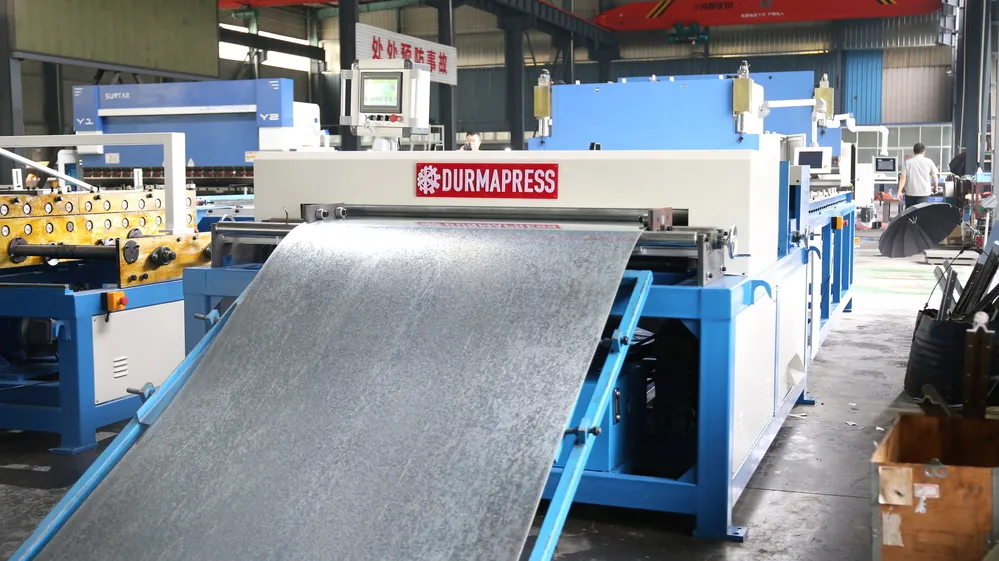

The most significant efficiency gain comes from workflow integration. An automatic duct line connects feeding, cutting, forming, and locking operations into a single production sequence.

Once parameters are set, material moves continuously through the line without stopping for repositioning or manual alignment. This eliminates waiting time between processes and ensures that each station operates in synchronization with the rest of the system. Integrated edge preparation processes, such as duct grooving, help maintain consistent material flow and reduce manual adjustment during production.

The result is a smooth production rhythm that is difficult to achieve with standalone equipment.

Reduced Manual Handling and Labor Dependency

Manual handling is one of the largest hidden costs in duct fabrication. Automatic duct lines significantly reduce the need for operators to lift, align, or transport sheet metal between machines.

By automating feeding and positioning, the system minimizes human intervention in repetitive tasks. Operators shift from manual processing to monitoring and adjustment roles, which reduces fatigue and improves consistency.

Lower labor dependency also makes production output more predictable, particularly during long shifts or high-volume projects.

Consistent Processing Speed and Quality

In an integrated duct production system, processing speed is controlled centrally. Each station operates according to synchronized parameters, preventing sudden slowdowns or mismatches.

This consistency directly improves quality. Uniform cutting lengths, stable forming profiles, and reliable seam locking reduce dimensional variation across duct sections. As a result, downstream assembly and installation become faster and require fewer adjustments.

Consistent quality is a critical component of factory efficiency, as it minimizes rework and material waste.

Key Efficiency Gains from Auto Duct Lines

The efficiency improvements provided by automatic duct lines are reflected across multiple operational metrics.

Factories typically experience more stable daily output, making production planning easier. Material utilization improves as cutting accuracy and forming consistency reduce scrap. Quality-related delays decrease because duct sections meet specifications more reliably.

Perhaps most importantly, production becomes scalable. As demand increases, output can be raised by adjusting production schedules rather than restructuring the entire workflow.

These gains are not limited to speed; they represent a more controlled and manageable manufacturing environment.

Auto Duct Line Efficiency vs Standalone Machines

Standalone duct machines remain valuable in many workshops, particularly for customized or low-volume work. However, their efficiency profile differs significantly from that of an integrated duct production line.

Standalone setups rely heavily on operator coordination. Production speed varies with skill level, and output consistency depends on careful supervision. While flexible, this approach becomes increasingly difficult to manage as production volume grows.

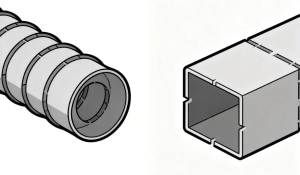

An automatic duct line, by contrast, standardizes the workflow. Efficiency is achieved through process coordination rather than individual performance. For factories focused on repetitive rectangular duct production, this shift delivers measurable long-term benefits.

Which HVAC Factories Benefit Most from Auto Duct Lines

Automatic duct lines are particularly effective in medium to large HVAC manufacturing facilities. Factories producing standardized duct sizes on a project basis benefit from the stability and repeatability of automated workflows.Mid-level systems such as Auto Duct Line 5 are commonly adopted by factories seeking stable output and improved workflow efficiency.

They are also well suited to operations facing labor shortages or high labor costs, as automation reduces reliance on manual processing. In environments where delivery schedules are tight and penalties for delay are high, predictable output becomes a strategic advantage.

While smaller workshops may not require full automation, growing manufacturers often view automatic duct lines as a necessary step in scaling their operations.

Efficiency Considerations When Choosing an Auto Duct Line

Efficiency gains depend not only on automation level but also on system alignment with production needs. A duct line that exceeds current requirements may introduce unnecessary complexity, while an undersized system can become a bottleneck.

Key considerations include expected production volume, duct size range, available floor space, and future expansion plans. Evaluating these factors ensures that efficiency improvements are sustainable rather than short-lived.

A well-chosen automatic duct line should support both current workloads and long-term growth.

Conclusion

Automatic duct lines improve HVAC factory efficiency by transforming isolated fabrication steps into a coordinated, continuous production process. Through reduced manual handling, synchronized operation, and consistent output quality, they enable manufacturers to meet growing demand with greater reliability.

In an industry where delivery timelines and quality standards continue to tighten, efficiency is no longer just a performance metric—it is a competitive requirement. For HVAC manufacturers seeking stable, scalable production, automatic duct lines represent a fundamental shift toward smarter manufacturing.

FAQ

Automatic duct lines improve efficiency by integrating multiple fabrication processes into a continuous workflow. This reduces manual handling, minimizes downtime between operations, and ensures consistent processing speed and output quality.

Traditional duct production often relies on standalone machines and manual material handling, which leads to workflow interruptions, variable production speed, and inconsistent quality—ultimately limiting factory efficiency.

Yes. By automating feeding, cutting, forming, and locking processes, automatic duct lines significantly reduce labor dependency for repetitive tasks, allowing operators to focus on monitoring and quality control.