In HVAC duct fabrication, producing accurate and consistent duct elbows is essential for ensuring smooth airflow and efficient system performance. Traditionally, forming duct elbows required significant manual labor and operator experience. Today, hydraulic duct elbow machines have transformed this process by delivering higher precision, repeatability, and production efficiency.

This article explains how a hydraulic duct elbow machine works—from sheet metal feeding to hydraulic forming—and walks through each key step of the HVAC duct elbow manufacturing process.

What Is a Hydraulic Duct Elbow Machine?

A hydraulic duct elbow machine is a specialized piece of sheet metal forming equipment designed to produce round or rectangular duct elbows for HVAC ventilation systems. By using hydraulic pressure and dedicated forming dies, the machine bends flat sheet metal into precise elbow shapes with controlled angles and diameters.

These machines are widely used in:

HVAC duct fabrication workshops

Commercial building ventilation projects

Industrial exhaust and air distribution systems

Sheet metal processing factories

Compared with manual elbow forming, hydraulic duct elbow machines offer improved consistency, reduced labor dependency, and higher output capacity, making them a standard solution in modern HVAC production lines.

Main Components of a Hydraulic Duct Elbow Machine

Understanding the machine structure helps explain how the forming process works. A typical hydraulic duct elbow machine consists of the following core components:

Hydraulic System

The hydraulic system is the power source of the machine. It includes the hydraulic pump, oil tank, valves, and cylinders. During operation, hydraulic pressure drives the forming action, allowing controlled bending of the sheet metal with stable force.

Forming Dies and Tooling

Forming dies determine the final elbow diameter and angle. Different tooling sets can be installed to accommodate various duct sizes and specifications. High-precision dies ensure consistent shaping and smooth elbow surfaces.

Feeding and Positioning Unit

This section supports sheet metal loading and alignment. Accurate positioning is essential for maintaining uniform elbow geometry and minimizing material waste.

Control System

Most machines are equipped with PLC or button-based controls, allowing operators to adjust forming parameters such as pressure, stroke, and cycle timing. Some models also support foot pedal operation for improved workflow efficiency.

Step-by-Step Working Process

The duct elbow manufacturing process follows a clear and repeatable sequence. Below is a typical workflow for a hydraulic duct elbow forming machine.

Step 1: Sheet Metal Loading

The process begins by placing the sheet metal—commonly galvanized steel, stainless steel, or aluminum—onto the feeding platform. Material thickness varies depending on application requirements, but hydraulic systems can handle a wide range of gauges.

Proper loading ensures stable forming and prevents surface damage during processing.

Step 2: Positioning and Alignment

Once loaded, the sheet metal is aligned with the forming dies. The positioning unit ensures the material sits correctly before hydraulic pressure is applied.

Accurate alignment at this stage directly affects the elbow’s final angle, diameter, and overall symmetry.

Step 3: Hydraulic Forming

This is the core stage of the process.

Hydraulic cylinders apply controlled pressure to the sheet metal through the forming dies. As pressure increases, the material gradually bends and conforms to the die shape. The hydraulic forming system allows smooth, continuous deformation, minimizing stress concentration and reducing the risk of cracking or distortion.

During this step, the duct elbow forming machine precisely shapes the metal to the required curvature and angle, typically ranging from 30° to 90°, depending on project needs.

Step 4: Elbow Shaping and Release

After reaching the preset forming position, hydraulic pressure is released. The finished duct elbow is separated from the dies, either automatically or manually depending on machine configuration.

At this point, the elbow has achieved its final geometry and is ready for inspection or downstream processing.

Step 5: Final Inspection

Operators check the formed elbow for:

Angle accuracy

Diameter consistency

Surface quality

Overall symmetry

Minor adjustments can be made by fine-tuning hydraulic pressure or tooling alignment for subsequent cycles.

Why Hydraulic Forming Is More Efficient Than Manual Methods

Compared with traditional manual elbow forming, hydraulic machines offer several clear advantages:

Higher consistency: Each elbow is produced under the same pressure and tooling conditions.

Reduced labor requirements: One operator can manage the entire forming cycle.

Improved productivity: Faster cycle times support batch production.

Better repeatability: Ideal for projects requiring uniform duct components.

These benefits make hydraulic duct elbow machines particularly suitable for medium- to high-volume HVAC fabrication.

Typical Applications in HVAC Duct Fabrication

Hydraulic duct elbow machines are commonly used in:

Commercial building ventilation systems

Industrial air handling projects

Factory exhaust ducting

Airports, hospitals, and shopping centers

Their ability to produce precise elbows ensures smooth airflow transitions and reliable system performance across diverse HVAC environments.

Factors That Affect Elbow Forming Quality

Several variables influence the final quality of duct elbows:

Material thickness: Thicker sheets require higher hydraulic pressure.

Hydraulic settings: Incorrect pressure may cause deformation or incomplete forming.

Tooling accuracy: Worn or misaligned dies reduce dimensional consistency.

Operator setup: Proper positioning and parameter adjustment are essential.

Regular maintenance and correct machine calibration help maintain stable production quality over time.

Conclusion

Hydraulic duct elbow machines play a critical role in modern HVAC fabrication by delivering consistent forming quality, improved efficiency, and reduced labor dependency. From sheet metal loading to hydraulic forming, each stage of the process contributes to accurate elbow geometry and reliable production results.

While understanding the working principle is essential, real-world performance also depends on selecting equipment that matches your material thickness, duct dimensions, production volume, and workshop conditions. Taking a structured approach to choosing the right hydraulic duct elbow machine helps ensure long-term stability, higher productivity, and better return on investment for your duct fabrication operations.

Frequently Asked Questions

What materials can a hydraulic duct elbow machine process?

Most machines handle galvanized steel, stainless steel, and aluminum commonly used in HVAC duct manufacturing.

Is hydraulic elbow forming suitable for high-volume production?

Yes. Hydraulic forming provides consistent quality and fast cycle times, making it ideal for batch and continuous production.

What elbow angles can be formed?

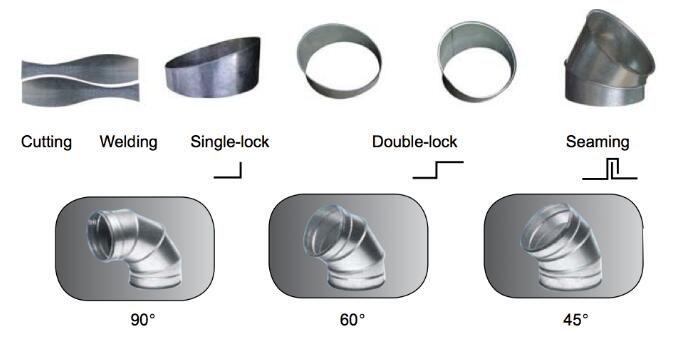

Standard configurations support angles such as 30°, 45°, 60°, and 90°, depending on tooling and machine design.

Does the machine require skilled operators?

Basic training is sufficient. Modern control systems simplify operation, allowing most workshops to achieve stable results quickly.