U SHAPE AUTO DUCT LINE V

U SHAPE DUCT AUTO LINE V

It’s mainly for TDF / angle steel / C-shaped flange forming with daily processing capability of 1000-2500 square meters. Only with inputting dimensions in duct, production line can automatically complete uncoiling, leveling, beading, punching, shearing, locking, forming TDF / angle steel / C-shaped flange and folding.

Basic Information

- During feeding mechanism with pneumatic servo, manipulator helps to ensure stability and speed of the machine, and the accuracy of its locating system.

- It only takes 20-25 seconds to make one L-shaped workpiece and the efficiency will double compared with the linear type.

- Without moving back and forth the fixed locking machine is able to improve the efficiency.

- All the rolling reels are made of bearing steel so that the lifetime prolongs by more than 5 times.

- Under the material-saving mode of CNC system, waste is less than 20 mm per roll.

- With production memory functions, the production orders can be tracked and checked.

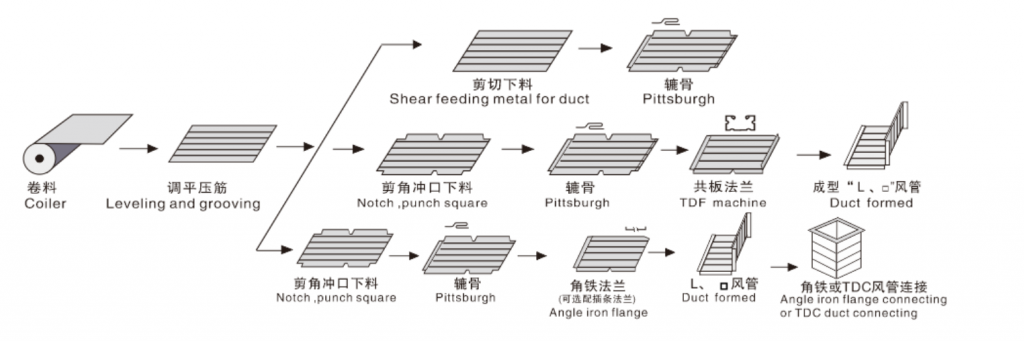

HVAC duct machine Working Schematic Diagram:

Main import Configuration:

- Japan Mitsubishi CNC control system

- Japan Omron encoder

- Taiwan Hiwin linear guideways

- Schneider electrical system

Basic Configuration:

- Two electric coil cradles, 4 material trays (5-7 t each roll)

- One rack One host (line 2 host)

- Two stainless steel roller convey platforms

- One fixed joint locking machine

- One duplex TDF flange forming machine

- One duplex angle steel flange forming machine

- One servo feeding platform

- One hydraulic folding machine

- One set of computer controlling system

Machine Frame

The machine frame adopts welding square steel,annealing treatment and overall processing toensure the stability and flatness of the frame and processing accuracy

PLC Control

Use Germany Siemens PLC controller whichcan accurately control the machining length,particularly suitable for production of ”L” and”口“-shaped pipe with different size.

TECHNICAL DATA

Model | Sheeting thickness (mm) | Max width (mm) | Max working speed (m/min) | Max weight of coil (T) | Dimension(mm)L*W*H | Power (kw) | Weight (T) | ||

DM-5U-1300 | 0.5-1.2 | 1300 | 15 | 7 | 14000 | 5000 | 1500 | 30 | 13 |

DM-5U-1500 | 0.5-1.2 | 1500 | 15 | 7 | 14000 | 5400 | 1500 | 30 | 14 |

Frequently Asked Questions

- You can choose the shipping company on your own. Or use our forwarder, we will quote you the CIF price.

- If less than one container,we will choose LCL (less container load), it will be cost-efficiency. If you purchase two and above, we will use 20″, 40″ or HQ container according to the machines size.

Durmahvac is a mature brand in China. We have CE, ISO and SGS certification to prove our quality. We welcome your visit, seeing is believing.

- T/T (30% advance payment, and 70% balance paid one week before shipment)

- L/C (100% L/C at sight), this should be negotiated first.

We always prepare stock for our clients. Contact us to learn more details.

Normally 15 days.