In industrial HVAC ductwork production, the spiral duct machine plays a central role in shaping high‑quality, leak‑proof ducts used in ventilation systems. From feeding the coil material to forming, seaming, and cutting, every detail affects the final product’s precision and durability.

Proper commissioning and maintenance not only ensure consistent performance but also extend equipment lifespan and minimize costly downtime. This guide walks you through each stage—from setup and calibration to daily maintenance and troubleshooting—so your spiral duct line always performs at peak efficiency.

Understanding the Spiral Duct Machine

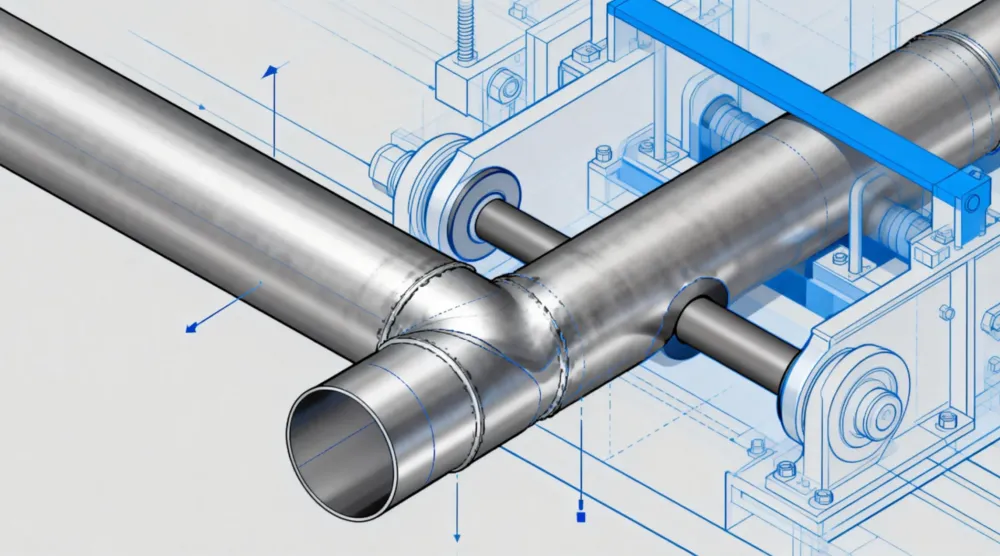

A spiral duct machine (also called a spiral tube former) forms metal strips into helical ducts by continuously rolling and locking the seam into shape. The typical system includes:

Coil feed system for aluminum, galvanized steel, or stainless steel sheets.

Forming head and rollers that determine duct diameter and roundness.

Lock seam mechanism ensuring airtight ducts.

Cutting unit (plasma or mechanical) to achieve precise lengths.

Control panel managing speed, diameter, and feed rate.

Different models—manual, semi‑automatic, or fully automatic—offer varied degrees of control and productivity. Understanding these components helps you perform accurate commissioning and maintenance later.

Commissioning Procedures

Proper commissioning starts before the machine ever runs.

Pre‑installation inspection: Check power supply, grounding, compressed air, and lubrication systems.

Mechanical alignment: Verify roller spacing and forming head centerline; misalignment causes seam leaks or wrinkles.

Parameter calibration: Set duct diameter, speed, and seam pressure per manufacturer specifications.

Trial production run: Produce several short ducts to test seam tightness, noise level, and cutting precision.

Performance verification: Record results and adjust feeding tension or roller pressure as needed.

Regular Maintenance Practices

Proactive maintenance ensures long‑term reliability and safety. Establish a schedule that includes daily, weekly, and monthly tasks:

Daily: Clean metal debris, check lubrication points, and verify safety guards.

Weekly: Inspect roller wear, adjust cutting blades, and check air filters.

Monthly: Align forming heads, recalibrate control settings, and examine all electrical connections.

Use approved cleaning agents and lubricants only—improper materials can damage roller surfaces or coatings. Replace worn components immediately to prevent chain reactions of mechanical failure.

Troubleshooting and Optimization Tips

Even well‑maintained machines may encounter performance issues. Typical symptoms include:

Uneven duct diameter: Usually caused by roller misalignment—recalibrate forming head.

Loose seam joints: Increase seam pressure or check lock‑seam tooling wear.

Excessive vibration: Inspect drive belts, bearings, and foundation bolts.

To optimize productivity, track feed speed, seam accuracy, and downtime statistics. Upgrading to automation (auto‑lubrication, servo drives) can also reduce human error and material waste.

Safety and Operator Training

Operator safety is non‑negotiable. Always:

Perform pre‑start checks for guards and emergency stops.

Keep hands and clothing away from moving rollers and cutters.

Use protective gear—gloves, eyewear, and ear protection.

Train new operators to read the control panel, interpret alarms, and execute emergency shutdowns.

Consistent training builds muscle memory for safe operation and helps reduce accidents in high‑speed production environments.

Conclusion

Commissioning and maintaining a spiral duct machine isn’t just a one‑time task—it’s a continuous process of inspection, calibration, and improvement.

Proper setup maximizes performance from day one, while a disciplined maintenance plan prevents breakdowns and ensures consistent duct quality.

When teams understand both the mechanical and operational aspects of the machine, they can run high‑efficiency HVAC duct lines that meet strict quality and energy standards.

FAQ

How does it differ from rectangular duct machines?

Spiral machines produce round ducts with fewer joints, reducing leaks and airflow resistance compared to rectangular systems, ideal for high-pressure HVAC.

How often replace parts?

Blades every 10,000m; rollers/bearings yearly or at wear signs like vibration/noise. Use OEM lubricants.

Why uneven duct diameter?

Roller gaps or coil tension issues—reset via control panel and test short runs.

Seams loose or leaking?

Worn lock-seam tooling or low pressure—inspect/replace, then reseal with EPDM if needed.

How to boost efficiency?

Automate feeds, track metrics (speed, waste), use corrugation for stiffness on large ducts (>250mm).