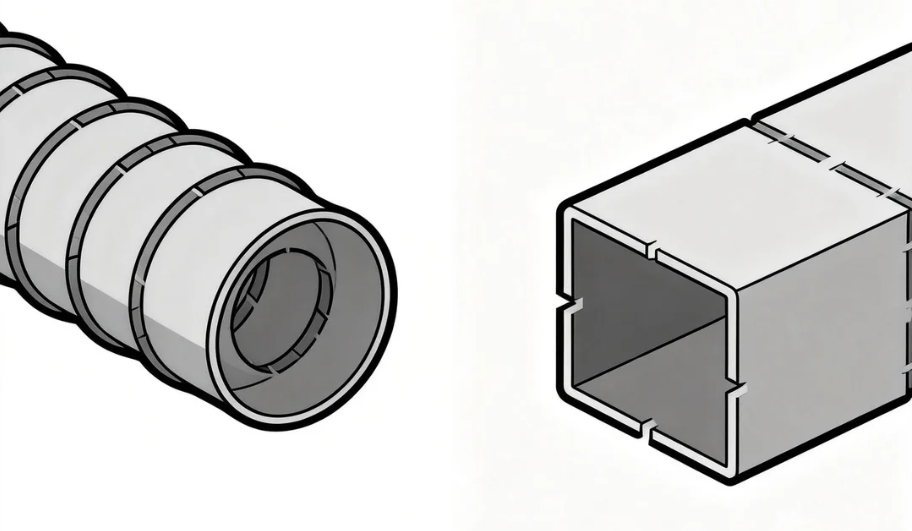

Spiral duct machines revolutionize HVAC fabrication by converting flat metal coils into robust, helical pipes in a continuous, high-speed process. These machines produce airtight ducts ideal for ventilation, exhaust, and air conditioning systems, offering superior strength and efficiency over traditional methods.

Machine Components and Setup

A full spiral duct production line features several integrated stations for seamless workflow. The hydraulic decoiler holds coils up to 2,000 lbs, feeding strips into multi-roller straighteners that remove curvature. The core forming head uses adjustable molds (80-2000mm diameters) and servo-driven rollers, followed by lockseam units and a flying saw cutter—all controlled via PLC touchscreen for parameters like pitch, length, and speed.

Before starting, verify coil specs: galvanized steel (most common), stainless, or aluminum at 0.4-1.6mm thick; ensure inner diameter matches the mandrel (typically 16-20 inches). Power up systems, zero encoders, and run a test strip to confirm alignment.

Step 1: Coil Loading and Decoiling

Load coils using a forklift or overhead crane, centering them on the decoiler’s expandable mandrel for a secure grip—critical to prevent slippage during high-tension feeding. Expand the mandrel hydraulically, engage the pressure arm to hold the outer edge, and cut ties from a safe side angle to avoid snap-back injuries.

Thread the strip end through entry guides and straightening rollers (usually 7-11 rollers), adjusting gaps to flatten without over-stressing the metal. Center the strip precisely using edge guides; inspect for rust, dents, or burrs that could jam later stages. This prep ensures even feeding at speeds up to 30m/min.

Step 2: Strip Forming into Helical Shape

The flat strip enters the forming head’s progressive rollers, which gradually curve it into a spiral based on mold size and pitch settings (e.g., 50-150mm for reinforcement ribs). Initial rollers create the radius, while subsequent ones overlap edges and wind continuously—forming a self-supporting tube without pausing.

Tension controls (pneumatic or servo) maintain uniform pressure, preventing wrinkles, gaps, or ovality (target <1% deviation). For larger diameters, wider overlaps enhance rigidity. Monitor via CCTV or gauges; common fixes include realigning rollers or slowing feed if waves appear.

Step 3: Seaming and Joint Locking

As the helix advances, overlapped edges (typically 15-20mm) pass under high-pressure seamers that cold-form a Pittsburgh or snap-lock joint—interlocking layers for airtight seals up to 10″ WG pressure. Multi-stage rollers squeeze progressively: first aligns, then embeds, finally flattens for a smooth, reinforced spiral seam.

This weld-free method avoids heat distortion, preserving galvanization. Adjust pressure per thickness (e.g., higher for 1.2mm); test seams with a leakage checker or hammer tap—dull sounds indicate loose fits. Quality seams boost system efficiency and meet SMACNA standards.

Step 4: Length Measurement and Precision Cutting

Inline encoders or laser sensors measure footage accurately (±1mm error), triggering the cutter at presets like 4-20 feet. Flying saws sync blade speed to pipe motion for burr-free cuts without stopping production; alternatives include hydraulic guillotines for thick gauges or plasma for stainless.

Post-cut, pipes eject to roller tables for cooling and inspection—check ends for squareness, deburr with grinders, and stack by size. Automate stacking for high volume to reduce labor.

Operational Benefits and Real-World Applications

These machines achieve 20-50 linear meters per minute, slashing labor by 70% and scrap to <5% via coil efficiency. Versatile for diameters up to 63 inches, they suit commercial buildings (air handling), factories (dust extraction), parking garages (smoke vents), and marine HVAC—where rigidity cuts supports needed.

Quick mold swaps enable multi-size runs in one shift, with low noise/vibration for shop use.

Troubleshooting Common Issues

| Issue | Causes | Fixes |

|---|---|---|

| Oval/ wrinkled pipe | Uneven tension, misaligned rollers | Re-gap rollers, check guidesconklinmetal |

| Loose/ leaky seams | Low pressure, poor overlap | Boost seamer force, verify pitchgfiductmachine |

| Length inaccuracies | Dirty encoder, slip | Clean sensors, calibrate PLCdurmahvac |

| Frequent jams | Burrs, wrong thickness | Inspect coils, adjust straightener |

Daily checks: lubricate bearings, sharpen saws, clean debris. Train operators on emergency stops.

FAQ

What materials work best with spiral duct machines?

Galvanized steel (DX51D grade, Z275 coating) is standard for rust resistance, with options for stainless or aluminum at 0.4-1.2mm thick. Match coil tolerance to avoid lockseam errors.

How to maintain the machine for reliability?

Lubricate gears daily, inspect rollers weekly, clean encoders monthly, and apply anti-rust grease during downtime. Schedule semi-annual overhauls.

Can it make different diameters and lengths?

Yes—swap molds for 80-2000mm diameters; PLC sets lengths precisely via flying saws, supporting batch runs without stops.

Are seams airtight without extra sealing?

Lockseams provide good seals (Class B/D per EN 12237), but add EPDM tape or silicone for high-pressure or corrosive apps.