TDF FLANGE FORMING MACHINE

首页 » TDF FLANGE FORMING MACHINE

Rectangular Duct Making Machine

- Contact Us

Brand: DURMAPRESS

Function

- Flange Forming for Air Ducts:Specialized in forming flanges at the plate connection ports of air ducts.

- Widely Used Connection System:One of the most commonly used flange systems in global duct production.

- Ideal for Small Section Ducts:Especially suitable for ducts with small cross-sectional areas.

- Efficient for Industrial Production:Supports large-scale manufacturing with high rigidity and smooth finish.

- Supports Automated Production Lines:Can be integrated with shearing, rib pressing, and flanging machines for automation.

- Compact Structure and Stable Performance:Tightly built and reliable, helping reduce production costs.

- Best Choice for Small Producers:Highly cost-effective and efficient—ideal for small-scale duct manufacturers.

Two Types of TDF Flange Forming Machines

TDF flange forming machines are divided into two types based on working needs: single flange and duplex flange machines.

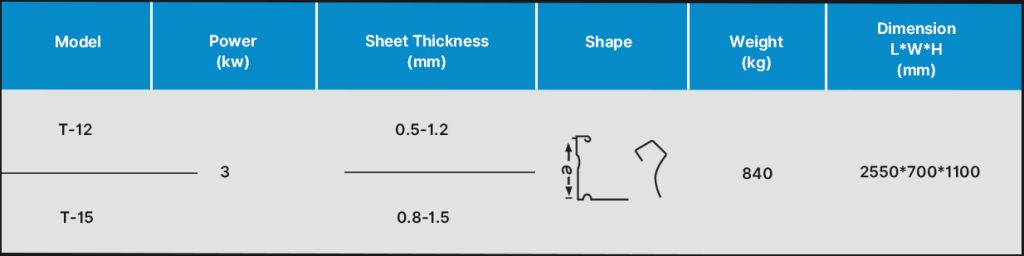

Single Flange Machine: T-12 & T-15 Models

The single flange machine forms a flange on one side and a clip on the other. Models include T-12 and T-15.

Duplex Flange Machine: Double-Side Forming

The duplex flange machine forms flanges on both sides simultaneously, saving time. It can also be customized to add clips.

Mobility & On-Site Use

The single flange machine is lighter and easier to move, often equipped with wheels. It’s ideal for on-site duct work due to its stability and convenience.

Part of Complete Duct Production Line

It works together with other rectangular HVAC duct machines such as:

- Lock former machine

- Pneumatic TDF folding machine

- Grooving machine

- Motor cutting machine

- Lock seaming machine

- Clips cutting machine

Maintenance Reminder

To keep machines running efficiently, regular maintenance is essential—especially lubricating key parts before operation.

Advantages:

1.Flange forming machine applies both sides manual feeding

2.Flange forming machines are available as single or duplex machines

3.Adding lubricating oil to ensure the efficient operation before using machines

It features low making cost and high installing efficiency, convenient for standard and batches of production. It is suitable for making rectangular air ducts with big sections.

1.2mm galvanized duct TDF flange machine, mainly used for making flange at edge of the plate for the connection of ventilation duct. It is also among basic equipment for modern duct forming lines. All bearings used are ball bearings rather than traditional needle bearings so that the machine will be more durable. The flange shape made by the machine is nicer and practical, which makes it a perfect part of the duct forming line.

Sheeting Thickness (mm):0.5-1.2

Dimension L*W*H(mm): 2700*700*1100

Total Power (KW):3

- Technical Data

- Production Details

- Finished product display & shipping packaging

Final Products

Choose advanced mechanical design technology, the motor and reducer are integrated to reduce the loss of transmission power

Shipping & Packing

Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

- Why Choose Us

Industry Experts

Professional HVAC Duct Machines Manufacturer

Perfect After-sales

24-hour after-sales response service

Engineer Overseas Service

Our engineers provide 24/7 on-site technical support

- Frequently Asked Questions

- You can choose the shipping company on your own. Or use our forwarder, we will quote you the CIF price.

- If less than one container,we will choose LCL (less container load), it will be cost-efficiency. If you purchase two and above, we will use 20″, 40″ or HQ container according to the machines size.

DURMAPRESS is a mature brand in China. We have CE, ISO and SGS certification to prove our quality. We welcome your visit, seeing is believing.

- T/T (30% advance payment, and 70% balance paid one week before shipment)

- L/C (100% L/C at sight), this should be negotiated first.

We always prepare stock for our clients. Contact us to learn more details.

Normally 15 days.

- Write Us